As we look toward the future, industrial automation is poised to play a transformative role in various sectors, significantly shaping the way businesses operate. The trends emerging in 2025 reflect a convergence of technological advancements that promise to enhance efficiency, improve safety, and optimize productivity across industries. From the rise of artificial intelligence and machine learning to the integration of the Internet of Things (IoT), these innovations are set to redefine operational paradigms and bring about a new era of smart manufacturing.

In this evolving landscape, understanding the top trends in industrial automation becomes essential for organizations aiming to stay competitive. As automation tools become more sophisticated, businesses will leverage data-driven insights to streamline processes and reduce downtime. Additionally, the increasing focus on sustainability will drive the adoption of eco-friendly automation solutions, reflecting a significant shift in corporate responsibility within the industrial sector. By 2025, those who embrace these trends will not only enhance their operational capabilities but also position themselves as leaders in an increasingly automated world.

As we move towards 2025, several emerging technologies are set to reshape the landscape of industrial automation. According to a recent report by Transparency Market Research, the global industrial automation market is expected to reach approximately $385 billion by 2025, driven by advancements in automation technologies and growing demand for operational efficiency. A key trend within this growth is the integration of Artificial Intelligence (AI) and machine learning algorithms into automation systems, enabling real-time decision-making and predictive maintenance. Research indicates that AI can enhance productivity by up to 20% in manufacturing processes, highlighting its transformative potential.

Additionally, the proliferation of IoT (Internet of Things) devices in industrial settings is revolutionizing data collection and monitoring capabilities. The Industrial Internet Consortium estimates that by 2025, there will be over 75 billion connected devices globally, many of which will operate within industrial environments. This extensive network of interconnected devices allows for enhanced data analysis and operational transparency, resulting in improved supply chain management and reduced downtime. Moreover, these technologies facilitate increased flexibility in production lines, as companies can rapidly adapt to changing market demands without significant overhead costs.

The coupling of these technologies not only streamlines manufacturing processes but also fosters greater sustainability. A report by McKinsey suggests that the adoption of automation and digital technologies could reduce operational energy consumption by up to 60%, directly contributing to environmental sustainability goals. As these trends continue to evolve, they indicate a promising future for industrial automation, emphasizing efficiency, connectivity, and sustainability as the cornerstones of innovation by 2025.

This chart displays the projected growth rate of key trends in industrial automation by 2025, highlighting the impact of emerging technologies.

The adoption of AI and machine learning in manufacturing processes is set to reshape the landscape of industrial automation by 2025. As manufacturers increasingly seek efficiency and cost-effectiveness, integrating these advanced technologies into their operations has become a strategic priority. AI algorithms can analyze vast amounts of data from production lines, enabling real-time decision-making that enhances productivity. Machine learning, in particular, allows systems to learn from historical data, improving their predictive capabilities for equipment maintenance and operational performance.

By utilizing AI and machine learning, manufacturers can optimize supply chains and reduce downtime through predictive analytics. This technology can forecast machinery failures before they occur, allowing for timely interventions and maintenance schedules that minimize disruptions. Furthermore, the ability to automate routine tasks not only alleviates the burden on human workers but also allows them to focus on more complex, value-added activities. As the adoption rates of these technologies increase, the industry can expect significant advancements in efficiency, quality control, and overall production agility, making AI and machine learning indispensable in the modern manufacturing ecosystem.

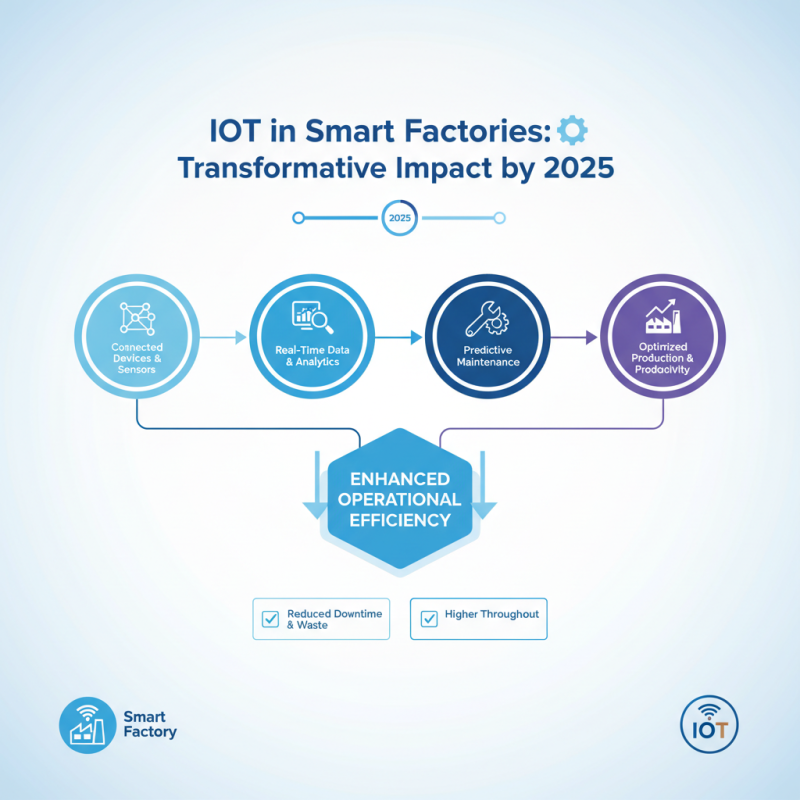

The impact of the Internet of Things (IoT) on smart factories is projected to be transformative, significantly enhancing operational efficiency by 2025. As industrial environments increasingly integrate connected devices and sensors, real-time data collection and analysis become paramount. This connectivity facilitates not only the monitoring of machinery but also predictive maintenance capabilities, allowing companies to address potential issues before they become disruptive. The seamless communication between devices leads to optimized production workflows, reducing downtime and waste, ultimately driving higher productivity levels.

Moreover, IoT enables manufacturers to gather valuable insights from their operations, fostering a more agile approach to decision-making. By leveraging big data analytics, businesses can identify trends and inefficiencies that may have previously gone unnoticed. This data-driven mindset empowers organizations to implement targeted improvements, streamline processes, and enhance overall operational efficiency. As factories embrace these technologies, they become more adaptable, capable of responding quickly to market demands and evolving customer preferences. The convergence of IoT within industrial automation not only fosters innovation but also sets the stage for a more sustainable and resilient manufacturing landscape.

As we approach 2025, the advancements in robotics stand out as key drivers of labor productivity in industrial automation. The integration of smart robots into manufacturing processes is not just about replacing human labor; it's about enhancing the capabilities of the workforce. These robots can now perform complex tasks with precision and speed, significantly reducing production times and minimizing errors. Industries are realizing that investing in robotic technology can lead to substantial returns, as workers can focus on higher-level, strategic functions while robots handle repetitive or hazardous tasks.

Tips for organizations looking to improve productivity through automation include assessing current workflows to identify bottlenecks that robots can address. Additionally, fostering a culture of collaboration between human workers and robots can lead to more efficient operations. Training employees to work alongside robotic systems is crucial, ensuring that they harness the technology's full potential and remain adaptable in an evolving workplace.

Moreover, the role of artificial intelligence in robotics further amplifies productivity. AI-enhanced robots can learn from their interactions and optimize processes in real-time. Companies should keep an eye on developments in machine learning algorithms that empower robots to analyze data and improve their operations autonomously. Embracing these advancements will position organizations at the forefront of industrial automation and boost overall productivity.

As the industrial landscape evolves, sustainability practices are increasingly becoming central to future automation strategies. Companies are recognizing that not only does sustainability drive compliance and brand reputation, but it also presents significant opportunities for innovation and efficiency. In 2025, automation will be heavily influenced by eco-friendly technologies that integrate energy-efficient systems, reduced waste protocols, and circular economy principles. These practices are set to transform traditional manufacturing processes, enabling industries to minimize their environmental footprint while maximizing production capabilities.

Additionally, the push for sustainable practices is leading to the adoption of smart manufacturing systems that utilize data analytics and AI to optimize resource use. By leveraging real-time data, organizations can enhance operational efficiency and reduce energy consumption, leading to more sustainable outcomes. The integration of renewable energy sources, such as solar and wind power, into automated systems will not only support corporate sustainability goals but also help businesses achieve long-term cost savings.

As we approach 2025, the synergy of industrial automation and sustainability will redefine how manufacturing operates, aligning economic success with ecological responsibility.