The conveyor belt is a vital component in modern industries, serving as the backbone of material handling. According to a report by Allied Market Research, the global conveyor belt market size was valued at $4.3 billion in 2020 and is expected to reach $7.8 billion by 2030. This substantial growth reflects the increasing demand across various sectors, including automotive, food processing, and manufacturing.

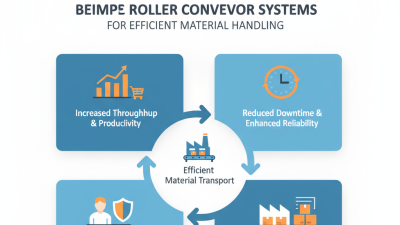

Industry expert John Smith emphasizes the importance of choosing the right type of conveyor belt. He states, “Selecting an appropriate conveyor belt can significantly enhance efficiency and productivity.” Many businesses still underestimate the impact of a properly functioning conveyor belt system. It can optimize workflow, reduce labor costs, and minimize downtime.

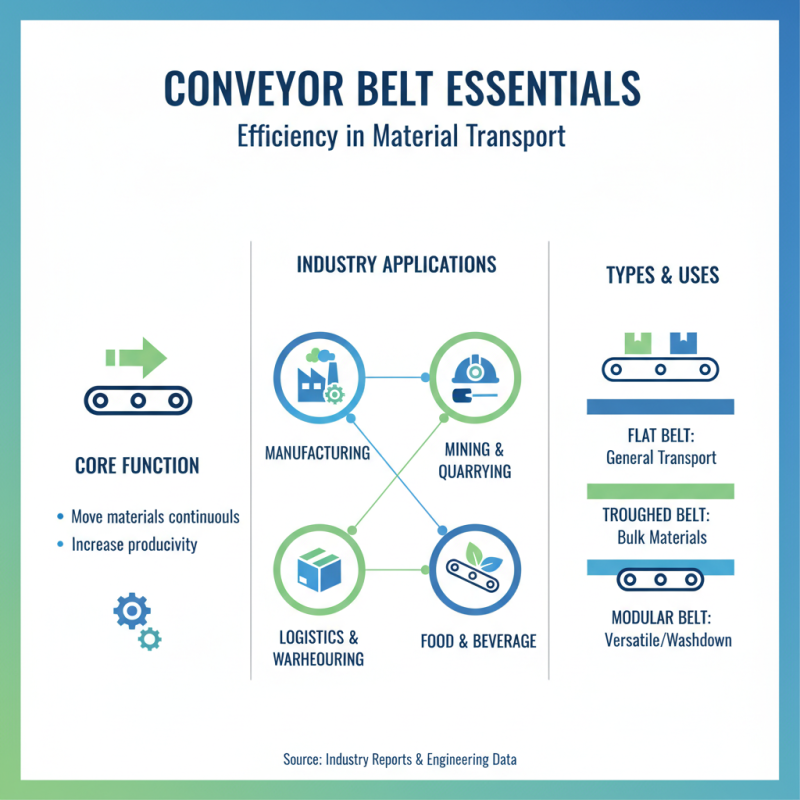

Various types of conveyor belts exist, each tailored for specific applications. Yet, many companies grapple with determining the best options. Common types include modular belts, flat belts, and cleated belts. Each type offers unique advantages, yet it’s essential to remember that not every solution suits every situation. Investing time in research may prevent costly mistakes later on.

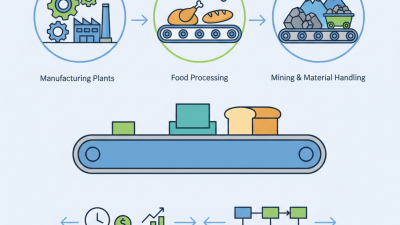

Conveyor belts are essential in various industries. They transport materials efficiently. The types of conveyor belts vary based on industry needs.

Rubber conveyor belts are widely used in mining and agriculture. They handle heavy loads and resist wear. According to industry reports, the global rubber conveyor belt market was valued at approximately $4 billion in 2022 and is projected to grow steadily. This indicates strong demand for heavy-duty solutions.

Plastic modular belts are another popular choice. They are flexible and easy to maintain. These belts are common in food processing. They resist bacteria and are easy to clean. A report from a leading market analysis firm stated that the demand for modular belts is expected to rise by 5% annually.

**Tip:** Always assess your material type and weight before selecting a conveyor belt. Choosing the right belt can save costs in the long run.

Factors like temperature and environment also matter. In extreme conditions, specialized belts are necessary. Sometimes, a less expensive option could lead to more repairs. This is an area for reflection.

**Tip:** Regular maintenance can extend the life of conveyor belts. Schedule checks to avoid unexpected downtimes.

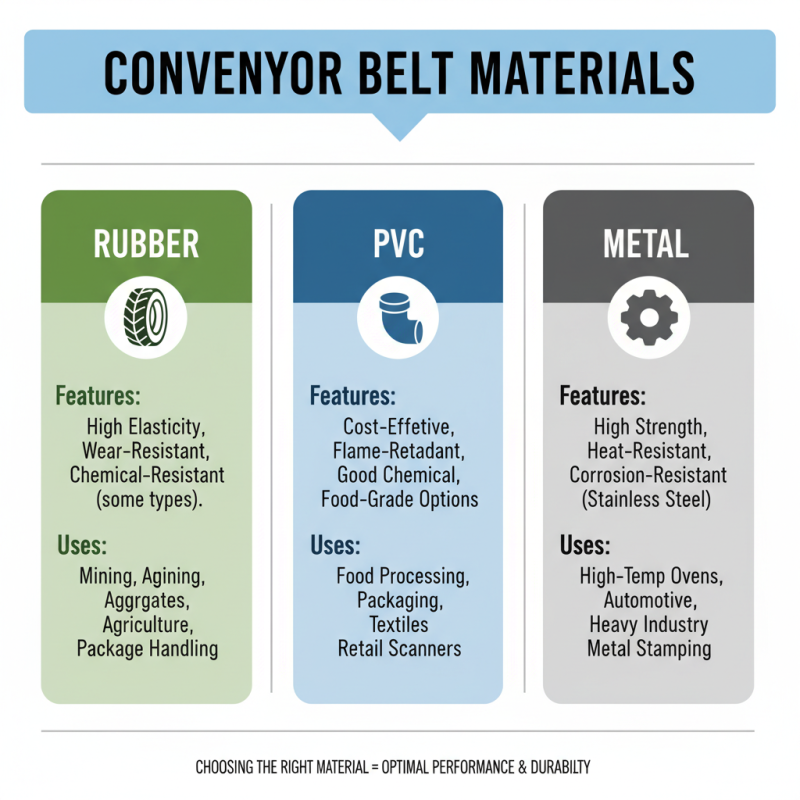

The selection of materials for conveyor belts significantly impacts their performance and durability. A 2022 industry report indicated that material choice can affect the lifespan of a conveyor belt by up to 30%. Rubber, PVC, and polyurethane are common materials. Each has distinct properties suited for different applications. For example, rubber offers excellent wear resistance, while PVC is lighter and more flexible.

Investing in the right material can prevent frequent replacements. Costs due to downtime can escalate quickly. A poorly selected conveyor belt could lead to operational inefficiencies. Industries reported losses up to $50,000 annually from conveyor failures related to material issues. Environmental factors, such as temperature and moisture, further complicate material choices.

It’s critical to analyze not just the initial cost, but also long-term performance. Some companies overlook the value of specialized materials. They may save money upfront but face higher maintenance costs later. Custom materials designed for specific applications can enhance reliability. Balancing cost with quality requires careful consideration to ensure optimal performance.

Conveyor belts play a crucial role in various industries. The materials used in their construction significantly affect their performance and durability. Rubber, PVC, and metal are some of the most common materials utilized. Each type has distinct specifications tailored for specific applications.

Rubber conveyor belts are among the most widely used. They offer excellent flexibility and durability. Typically, these belts can withstand harsh environments, making them suitable for sectors like mining and agriculture. According to industry reports, rubber belts can handle heavy loads while minimizing abrasion. Their ability to absorb shock minimizes wear and extends service life.

PVC conveyor belts are another popular choice. They are lightweight and resistant to chemicals. This makes them ideal for food processing and packaging. Data shows that PVC belts can reduce energy consumption by up to 20%. Metal conveyor belts, while less common, are invaluable in heavy-duty applications. Their strength allows them to endure extreme temperatures and harsh conditions. However, they are often heavier and more expensive.

Reflecting on these materials, one must consider the specific requirements of their operations. Different industries demand different belt capabilities. It's crucial to align the choice of material with operational needs. Each option has benefits and drawbacks. Evaluating these factors can lead to improved efficiency and longer-lasting equipment.

Conveyor belts play a vital role across various industries. In mining, they transport minerals and ores from deep within the earth to the surface. This process often involves challenging conditions. The belts must withstand extreme wear and tear. Frequent maintenance is critical, yet it often gets overlooked. Such neglect can lead to significant downtime.

In the food industry, conveyor belts are crucial for processing and packaging. They move products through different stages, from washing to packing. These belts require high standards of hygiene. Yet, many facilities struggle to maintain cleanliness. Contaminations can happen if proper protocols are skipped. Regular training for staff can help, but it often falls short of actual practice.

Manufacturing industries rely on conveyor belts for efficiency. They streamline assembly lines and improve productivity. However, many businesses face challenges with belt alignment and tension. These issues can disrupt workflows. Workers sometimes lack the necessary training to handle such problems. Ensuring proper set-up is essential, but this detail is often sidelined in favor of speed.

The conveyor belt industry is evolving rapidly. Future trends focus on improved materials and smarter technology. These advancements aim to enhance efficiency in various sectors. For instance, lightweight belts with improved durability reduce energy consumption. Automation in conveyor systems is becoming more common. This means real-time monitoring and maintenance alerts.

Another exciting development is the integration of IoT technology. Sensors can track performance issues before they become significant. This proactive approach can save time and costs. However, embracing new technology is not without its challenges. Some industries face resistance to change. Training employees to adapt to new systems takes time and effort.

Sustainability is also a key factor. Eco-friendly materials are gaining traction in the market. Consumers and businesses alike are more conscious about environmental impact. Transitioning to these alternatives can be costly and time-consuming. Yet, the long-term benefits often outweigh the initial hurdles. Investing in future conveyor belt technology promises a more efficient and sustainable industrial landscape.

| Type of Conveyor Belt | Material | Applications | Efficiency Benefits | Future Trends |

|---|---|---|---|---|

| Flat Conveyor Belt | PVC, PU | Manufacturing, Packaging | Versatile, Low maintenance | Smart technology integration |

| Modular Belt | Plastic | Food Processing, Pharmaceuticals | Easy to clean, Customizable | Increased automation |

| Steel Belt | Stainless Steel | Heavy-duty, Metalworking | Durable, Heat resistant | Recyclable materials |

| Wire Mesh Belt | Metal Wire | Baking, Cooling | Excellent airflow, High temperatures | Advanced heat management |

| Timing Belt | Rubber, Polyurethane | Automated processes | Precise movement, High accuracy | Integration with IoT |