In today's competitive market, streamlining packaging processes is essential for any business. A case packer can be a transformational tool for efficiency. John Smith, a leading expert in packaging technology, states, "Investing in a case packer can drastically reduce costs and improve productivity." His insight resonates with many businesses looking to optimize operations.

Using a case packer not only saves time but also enhances consistency in packaging. Imagine a production line where each carton is packed uniformly. The reduction in human error is significant. However, some companies still hesitate due to initial investment costs. This hesitation often leads to missed opportunities for growth and efficiency.

Additionally, adopting a case packer can open doors to scalability. As demand increases, businesses can respond swiftly. Yet, it’s vital to assess the specific needs carefully. Not every case packer may suit every business model perfectly. Regular reflection on performance and needs ensures that investments yield the best results.

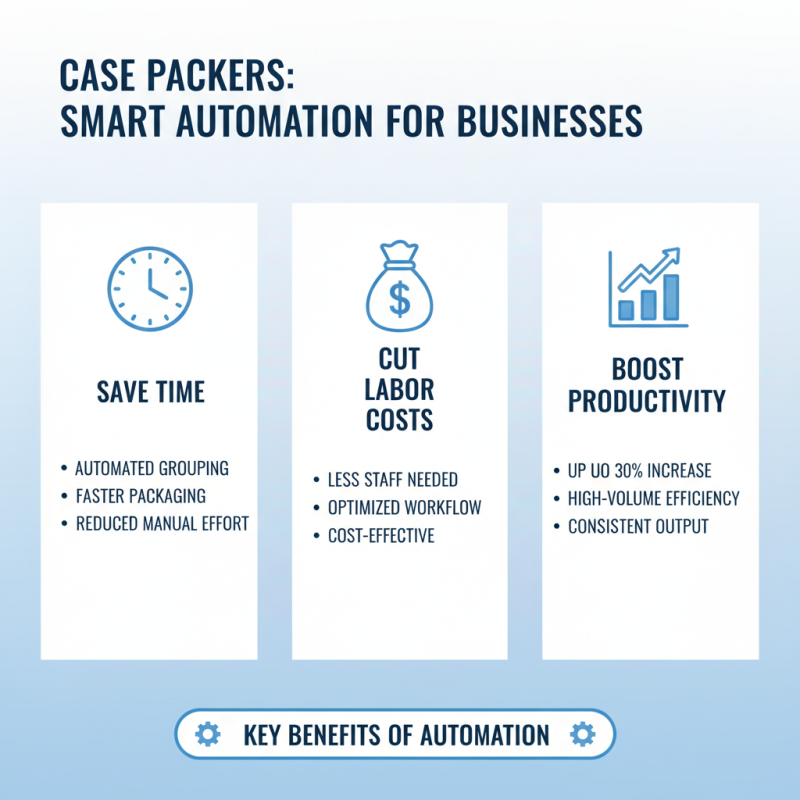

Case packers are essential machines that automate the packaging process for businesses. They handle the grouping and packing of products into cases efficiently. By using case packers, companies can save time and manage labor costs effectively. Industry data indicates that automation can increase productivity by up to 30%, particularly in high-volume settings.

The workings of a case packer involve a series of mechanical actions. Products move through the machine on conveyor belts and are guided into formation. Once in position, the case packer folds and seals the case. This process minimizes human error and reduces product damage during packing. However, implementing such technology requires upfront investment and proper training, which many businesses overlook.

Tip: Regular maintenance of case packers is crucial. Neglecting this can lead to costly downtimes. Moreover, ensure that employees receive ongoing training to fully utilize the machine's capabilities. Another consideration is to assess your production volume frequently. An underused system can result in wasted resources. Balancing efficiency with practical usage is vital for maximized output.

In the fast-paced world of logistics and manufacturing, enhanced efficiency is crucial.

Case packers play a vital role in streamlining packaging processes. Automation is the key.

According to a 2021 report by the Packaging Machinery Manufacturers Institute, automated systems can increase packaging speed by up to 50%.

This is significant for businesses seeking to meet rising consumer demand.

A case packer reduces the manual labor required for packaging. Workers are often assigned repetitive tasks, leading to fatigue and errors.

An automated system takes over these tasks, allowing human resources to focus on more complex activities.

Interestingly, a study from the International Society of Automation found that over 40% of companies that adopted case packing technology saw a 30% reduction in packaging errors.

This is noteworthy but raises the question of training staff to manage new technologies effectively.

While case packers enhance efficiency, they also introduce challenges.

Initial costs can be high, and not all businesses may see immediate returns.

Maintenance and technical issues can also hinder performance.

A 2020 survey indicated that 35% of firms reported operational disruptions due to machinery malfunctions.

It’s essential for companies to weigh these factors against the long-term benefits of automation in their packaging processes.

Implementing case packers can lead to significant cost savings for businesses. These machines automate the packing process, reducing labor costs considerably. Businesses might expect to cut staffing needs by at least 20% with effective automation. Lower labor expenses can greatly enhance profit margins, allowing companies to allocate funds to crucial areas like marketing or product development.

However, investing in case packers requires careful consideration. The initial setup cost can be high. Businesses must evaluate whether the savings in labor justify the investment in machinery. Maintenance costs are another factor. An unexpected breakdown can lead to downtime, impacting production schedules. Additionally, training staff to utilize these machines effectively can require time and resources.

While the potential for savings is appealing, the transition may also present obstacles. Some companies might face resistance from employees accustomed to manual packing. Addressing this resistance is crucial for smooth integration. Regular assessments of the packing process post-implementation can help identify areas needing improvement. Balancing automation with workforce satisfaction can be a challenging yet rewarding endeavor.

Using a case packer can significantly improve product protection. These machines ensure that items are securely packed for transit. According to industry data, proper packaging can reduce product damage rates by up to 15%. This reduction translates to lower costs and higher customer satisfaction.

Case packers create uniformity in packaging. This consistency aids in stacked loading during transportation. Stacked boxes are less likely to shift or collapse, safeguarding the contents inside. Small adjustments can lead to significant improvements in safety. The right case packer can adapt to different box sizes, enhancing flexibility.

Tips: Regular maintenance of case packing machines is essential. Even minor wear can lead to inconsistencies in packing. Training staff on proper loading techniques can also improve packing efficiency. Investing time in these areas can yield better results. Evaluating packaging materials can lead to cost savings. Using thinner, durable materials may protect products while reducing costs.

In today’s fast-paced market, businesses need adaptable solutions. Case packers provide scalability and flexibility. They can easily adjust to different production volumes. This means businesses can start small and grow bigger without disrupting their operations. Customizing the packaging process allows for smoother transitions, especially during peak seasons.

Adapting case packers to specific business needs opens new avenues. For instance, they can handle various packaging formats, from cartons to more specialized containers. However, companies might face challenges in perfecting these adjustments. Not every transition goes smoothly; sometimes, employees require extra training. An implementation phase can reveal gaps in workflows that demand immediate attention.

Innovating packaging with case packers can lead to enhanced efficiency. Yet, it’s crucial to ensure the machines align with existing processes. Businesses may need to rethink layouts or retrain staff. Continuous evaluation of the packing process is essential. Flexibility brings opportunities, but it also comes with a need for ongoing reflection.

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Efficiency | Automates packaging processes, reducing manual labor. | Speeds up production times, allowing for higher output. |

| Flexibility | Easily adjusts to accommodate different product sizes and types. | Meets varying demand and packaging needs without major changes. |

| Cost Savings | Reduces labor costs and material waste through optimized packaging. | Lower operational costs increase overall profitability. |

| Consistent Quality | Delivers uniform packaging results across production batches. | Improved brand reputation through quality assurance. |

| Scalability | Can scale operations up or down based on market demands. | Supports business growth without requiring significant new investments. |

| Safety | Lowers the risk of workplace injuries associated with manual packaging. | Creates a safer working environment, improving employee satisfaction. |

| Data Tracking | Integrates with software for real-time tracking of packaging processes. | Enhances decision-making with accurate data and insights. |

| Sustainability | Optimizes the use of eco-friendly materials and reduces waste. | Promotes a positive image among environmentally conscious consumers. |

| Improved Supply Chain | Streamlines packaging, aligning closely with logistics and distribution. | Boosts overall operational efficiency across the supply chain. |