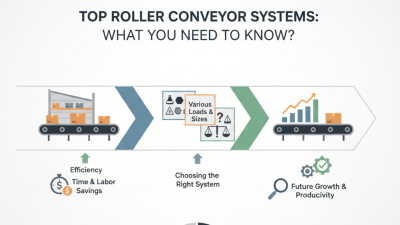

In the dynamic world of logistics and manufacturing, the role of the roller conveyor belt is pivotal. According to a recent report by the Material Handling Industry of America, efficient material handling systems can improve productivity by 25% or more. This highlights the necessity of investing in quality roller conveyor belts. They minimize downtime and enhance workflow, vital for competitive advantage.

Expert Michael Johnston, a leading authority on material handling solutions, states, “The right roller conveyor belt can revolutionize your operations.” This underscores the importance of selecting the best options available. Companies that ignore this may face increased costs and inefficiencies. The choices can be overwhelming, yet understanding the right specifications is crucial.

Selecting an efficient roller conveyor belt not only impacts performance but also shapes overall business success. Buyers must consider factors like material durability and load capacity. Small misjudgments can lead to significant setbacks. Making the right choice at this juncture is imperative for optimizing logistics and enhancing operational integrity.

Roller conveyor belts play a crucial role in material handling systems. They are designed to transport goods smoothly and efficiently. The belts consist of rollers that support and move items from one point to another. This mechanism reduces manual labor and speeds up operations in warehouses and manufacturing plants. According to industry reports, efficient conveyor systems can improve productivity by up to 30%.

One common application of roller conveyor belts is in assembly lines. They facilitate the quick movement of products between workstations. The speed can often be adjusted, allowing for optimal workflow. However, not all systems are easy to maintain. Regular maintenance is essential to avoid costly downtimes. Without proper care, roller misalignment can occur, disrupting the workflow.

**Tips:** When selecting a roller conveyor, consider the weight and size of the materials. Overloading can lead to system failure. Also, ensure that the environment is suitable for the chosen belt type.

Another useful insight is to invest in advanced sensors. They can provide real-time monitoring of the conveyor system. This technology helps identify issues before they escalate. However, the initial investment may be high, prompting companies to reflect on their long-term needs. Balancing cost and efficiency remains a common challenge.

This chart presents the load capacity of the top 10 roller conveyor belt options, showcasing their efficiency in material handling. Each belt's capacity varies, making them suitable for different applications in various industries.

When selecting a roller conveyor belt, several key factors come into play. The weight capacity of the conveyor is crucial. Heavy loads require sturdy belts that can withstand stress. Consider the type of materials being transported. Some belts work better with certain materials. This choice impacts the efficiency of your operations.

**Tip:** Always measure the dimensions of your materials. This ensures that the conveyor belt fits well and functions efficiently.

Another aspect to think about is the environment. Will the conveyor be outdoors? Exposure to weather elements can wear belts down faster. Choose materials that resist rust and corrosion for outdoor applications.

**Tip:** Regularly inspect your conveyor system. This helps identify wear and tear before it becomes a major issue.

Speed is another consideration. Determine the optimal speed for transporting your loads. A speed that’s too fast may cause accidents. Polarize between efficiency and safety to find the right balance.

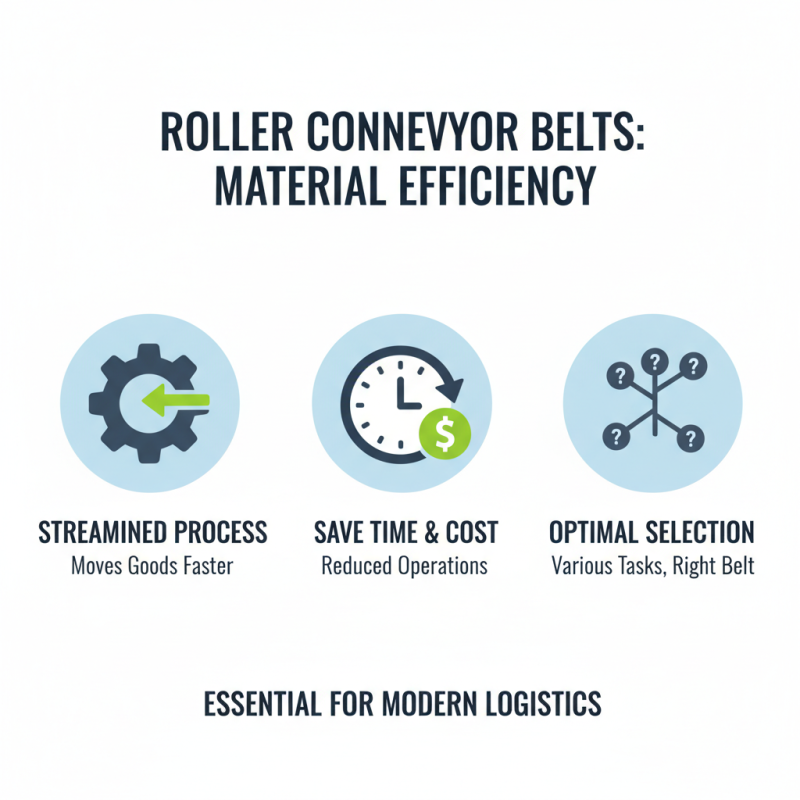

When it comes to material efficiency, roller conveyor belts are essential. They streamline the process of moving goods. The right belt can save time and reduce operational costs. Different options may suit various tasks. Choosing the best roller conveyor can be daunting.

To enhance efficiency, consider the weight and size of your materials. Lighter items may need a different belt compared to heavier loads. It's also important to assess the layout of your workspace. Proper alignment can avoid jams.

Tips: Regular maintenance is key. Check for wear and tear monthly. This can prevent costly breakdowns. Don't forget to adjust the speed of the belt to match your workflow. A mismatch can lead to delays.

Different materials require various features. Some belts are designed for heavy loads, while others focus on speed. Review your specific requirements carefully. Sometimes, a less popular option may fit your needs better. Flexibility in your choice may lead to unexpected benefits.

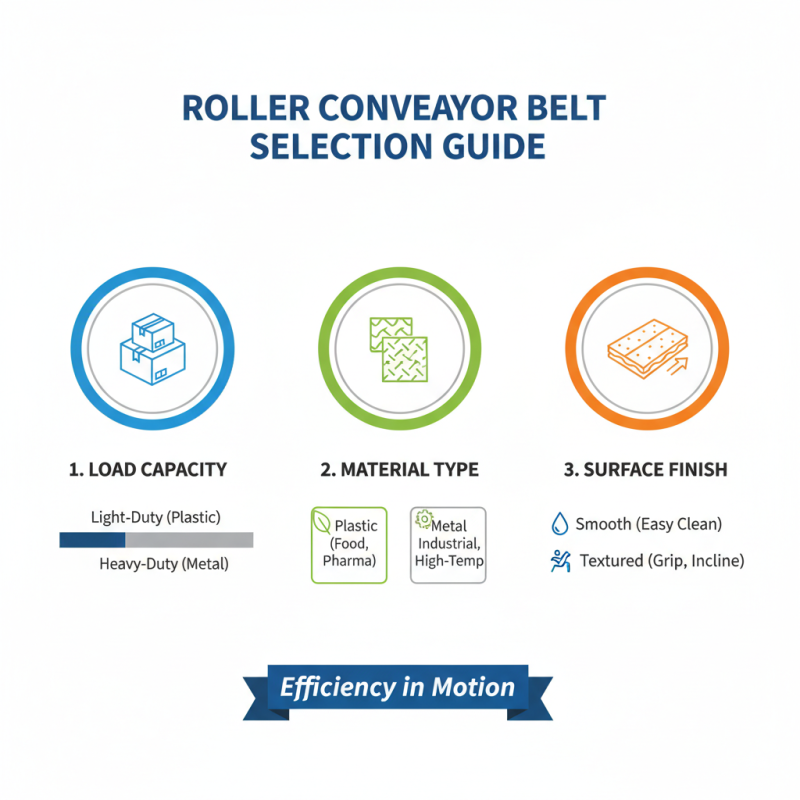

When selecting roller conveyor belts, various features play a vital role in efficiency. Key considerations include load capacity, material type, and surface finish. Different materials are suited for distinct environments. For example, plastic belts work well in light-duty scenarios. Metal belts, on the other hand, are often better for heavier loads.

The surface finish is also important. Grooved finishes help with grip, preventing slippage during transport. This is crucial in fast-paced operations where safety is a priority. However, some grooves may complicate cleaning. A simple surface may be easier to maintain but can lack traction.

Another factor is belt width and length. Wider belts can accommodate more products simultaneously. Yet, wider belts may be more challenging to integrate in smaller spaces. Length adjustments can also affect speed. Longer conveyors may reduce efficiency if not properly powered. Thus, balancing these features is essential for optimal operations while also being mindful of potential challenges.

Proper maintenance of conveyor systems is crucial for optimal performance. According to industry reports, unmaintained systems can lead to a 30% decrease in efficiency. Regular inspections can help identify potential issues before they escalate. Common problems include misaligned belts, worn rollers, and dirty systems. These issues can cause unexpected downtime and increased operational costs.

Lubrication is key to keeping the rollers and belts in top shape. It's important to use the right type of lubricant, but many facilities overlook this detail. Insufficient lubrication can lead to wear and tear, reducing the lifespan of the components.

Cleaning the conveyor regularly is equally vital. Dust and debris can cause friction, leading to failures. Maintenance teams should establish a cleaning schedule to prevent these problems.

Tracking the performance metrics of conveyor systems can reveal insights. An increase in downtime, or a drop in output, signals a need for maintenance. Neglecting these signs can be costly. Understanding the specific needs of different systems enhances overall efficiency. However, it's easy to overlook the small details.

Small tweaks often lead to big gains in productivity.