In today's highly competitive manufacturing environment, optimizing production efficiency is more crucial than ever. A recent report by Research and Markets indicates that the global packaging automation market is projected to reach USD 92.81 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.68%. This growth underscores the vital role that packaging automation plays in enhancing operational effectiveness and reducing costs across various industries. By automating packaging processes, companies can not only streamline their operations but also respond more rapidly to market demands, thus gaining a competitive edge.

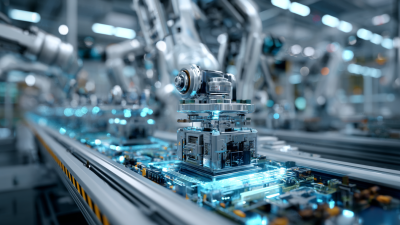

According to industry expert Dr. Emily Carter, a renowned authority in packaging technology, “The integration of packaging automation into production lines is no longer a luxury, but a necessity for companies aiming to improve their efficiency and reduce time-to-market.” As organizations strive to meet the increasing consumer demand for faster delivery and more sustainable practices, packaging automation serves as a key driver in achieving these objectives. Harnessing the power of advanced technologies such as robotics, artificial intelligence, and IoT can lead to significant improvements in accuracy, speed, and reliability in packaging operations, paving the way for a more efficient and successful production process.

Packaging automation plays a crucial role in streamlining production processes by enhancing speed, accuracy, and efficiency. In a modern manufacturing environment, the demand for rapid product turnaround requires systems that can adapt to various sizes and formats without sacrificing quality. Automated packaging solutions minimize human error by employing precise machinery that consistently delivers accurate packaging results, thus reducing waste and ensuring product integrity.

Moreover, the integration of automation into packaging lines can significantly reduce labor costs and increase throughput. By automating repetitive tasks, such as filling, sealing, and labeling, manufacturers can redirect their workforce towards more strategic roles that require human oversight and innovation. This shift not only boosts overall production capacity but also allows for a more agile response to market demands, ultimately enhancing competitiveness in an ever-evolving landscape. Therefore, the role of packaging automation is not just about efficiency but also about enabling manufacturing operations to thrive in a fast-paced environment.

Automated packaging solutions are becoming indispensable for companies aiming to optimize production efficiency. The integration of such technologies can significantly reduce labor costs and minimize human error, leading to higher output rates. For instance, companies are increasingly adopting advanced packaging systems to keep pace with the rising demand for faster production lines. This transition not only enhances packaging precision but also ensures that products are brought to market more swiftly.

Tips: When considering automation, assess your current workflow to identify bottlenecks. This analysis will help determine which packaging solutions can enhance your operations most effectively. Additionally, consider investments in technologies like EtherCAT, which can dramatically improve the efficiency of equipment used in high-speed packaging processes.

Furthermore, as the pharmaceutical industry evolves, implementing automated systems in manufacturing can lead to substantial benefits. With the shift towards more complex drug formulations and packaging, staying aligned with advanced technologies is critical. Automation can not only streamline processes but also contribute to compliance with regulatory standards by ensuring accuracy and traceability in production lines. Embracing these changes will position companies as leaders in the ever-competitive market.

Packaging automation plays a pivotal role in reducing labor costs within production facilities. By integrating automated systems, companies can significantly minimize their dependence on manual labor, which often entails higher wage costs and increased training expenses.

Packaging automation plays a pivotal role in reducing labor costs within production facilities. By integrating automated systems, companies can significantly minimize their dependence on manual labor, which often entails higher wage costs and increased training expenses.

With machines handling tasks such as filling, sealing, and labeling, businesses can streamline their workforce, allowing human efforts to focus on more complex and value-added activities. This shift not only leads to direct cost savings but also enhances overall workforce productivity.

Moreover, packaging automation contributes to increased output, enabling companies to meet growing consumer demands efficiently. Automated systems operate at faster speeds compared to manual packing processes, resulting in higher product throughput.

With precise and consistent packing capabilities, the risk of errors and defects is greatly reduced, further bolstering production rates. As such, companies employing packaging automation can respond more effectively to market fluctuations and fulfill orders swiftly, ultimately enhancing their competitive edge in the marketplace.

Automated packaging systems play a crucial role in enhancing quality control in manufacturing processes. By integrating advanced technologies such as machine learning and computer vision, companies can monitor packaging lines in real-time, ensuring that products meet precise quality standards. These intelligent systems can detect defects, measure fill levels, and verify the integrity of seals, reducing the likelihood of human error that could compromise product safety and performance. Consequently, businesses are not only able to maintain compliance with regulatory requirements but also reinforce customer trust through consistent quality.

Moreover, the significant growth in the automated packaging market, projected to reach USD 162.2 billion by 2035, underscores the industry's shift towards automation as a strategic approach to optimizing production efficiency. Organizations are adapting to these innovations to enhance operational performance while keeping costs manageable. Automation not only streamlines packaging processes but also contributes to a more sustainable manufacturing environment by minimizing waste and maximizing resource utilization. By prioritizing automated solutions, manufacturers are setting a new standard in quality assurance, ultimately leading to improved customer satisfaction and competitive advantage.

As industries strive for greater efficiency, packaging automation is becoming increasingly essential. The future trends in packaging automation focus on integrating advanced technologies that streamline production processes and reduce waste. One such trend is the incorporation of artificial intelligence and machine learning, which can analyze data in real-time to optimize packaging lines. By predicting maintenance needs and adjusting workflows, these technologies ensure minimal downtime and maximum output.

Another significant trend is the rise of collaborative robots, or cobots, that work alongside human operators. These robots are designed to enhance productivity by taking on repetitive tasks, allowing human workers to focus on more complex activities that require problem-solving and creativity. Furthermore, the integration of IoT devices offers invaluable insights into production metrics, enabling companies to monitor performance continuously and make data-driven decisions. As these technologies evolve, organizations that adopt packaging automation will not only enhance their production efficiency but also secure a competitive edge in the market.