In today’s rapidly evolving industrial landscape, the significance of manufacturing automation cannot be overstated. An increasing number of companies are recognizing that leveraging advanced technologies not only enhances operational efficiency but also drives innovation and competitiveness. According to a report by the International Federation of Robotics, the deployment of industrial robots in manufacturing has surged by over 14% annually, indicating a remarkable shift towards automated solutions that can significantly reduce costs while improving product quality.

Experts in the field, such as Dr. Emily Chen, a leading figure in manufacturing technologies, emphasize that “embracing manufacturing automation is no longer a choice but a necessity for any organization aiming to thrive in the modern economy.” Her insights highlight the critical role that automation plays in streamlining production processes, reducing human error, and meeting the increasing demand for customization and speed in production lines. This transformative approach enables manufacturers to adapt to market changes swiftly, thus ensuring sustainable growth.

As businesses continue to face challenges such as labor shortages and rising consumer expectations, integrating manufacturing automation into their operations will be vital. With a projected growth rate of 10% in the automation market over the next five years, organizations that harness these technologies stand to gain a significant competitive edge, positioning themselves for long-term success in an increasingly automated world.

Manufacturing automation plays a crucial role in enhancing production efficiency, driving significant advancements in modern industry. According to a report by McKinsey, companies that adopt advanced automation technologies can increase their productivity by up to 30%. This boost in efficiency is primarily achieved through streamlined operations, reduced cycle times, and improved resource allocation. Additionally, by automating repetitive tasks, manufacturers can minimize human error, which enhances quality control and product consistency.

Cost reduction is another vital benefit of implementing automation in manufacturing processes. A study by Deloitte indicates that companies utilizing automation can lower their operational costs by approximately 20-25% over a five-year period. Automation not only reduces labor costs but also optimizes the usage of materials and energy, leading to substantial savings. By investing in modern automated systems, manufacturers can achieve greater scalability and responsiveness to market demands, ensuring they remain competitive in an increasingly globalized economy.

The integration of automation in manufacturing processes is significantly transforming product quality and consistency, becoming a cornerstone for success in modern industry. According to a report by McKinsey & Company, manufacturing companies that have adopted automation technologies have seen up to a 30% reduction in defects and a 20-25% improvement in product consistency. This remarkable enhancement can be attributed to automated systems that ensure precision and repeatability, factors that manual processes often struggle to achieve.

Moreover, a study by the National Institute of Standards and Technology (NIST) indicates that firms implementing automation enjoy a 15% increase in overall productivity and a corresponding uplift in customer satisfaction due to the consistent quality of products delivered. As competition intensifies, manufacturers are leveraging automation not just to maintain quality but also to exceed customer expectations. With a higher product yield and fewer errors, these companies are better positioned to respond to market demands and reduce waste, demonstrating that automation is not just a strategy for efficiency but a vital component in enhancing product quality and reliability.

| Aspect | Before Automation | After Automation |

|---|---|---|

| Product Quality | Variation in product quality, with significant defects | Consistent quality with reduced defect rates |

| Production Speed | Manual processes leading to slower production times | Increased speed, with higher output per hour |

| Labor Costs | Higher labor costs due to manual operations | Reduced labor costs through automation |

| Consistency in Production | Inconsistent output due to human error | Highly consistent output with minimal variation |

| Time to Market | Longer time to market due to slower processes | Faster time to market with streamlined processes |

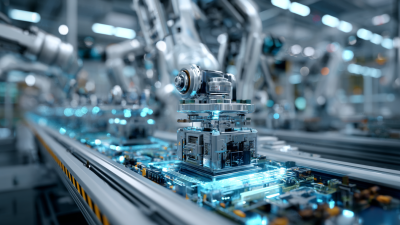

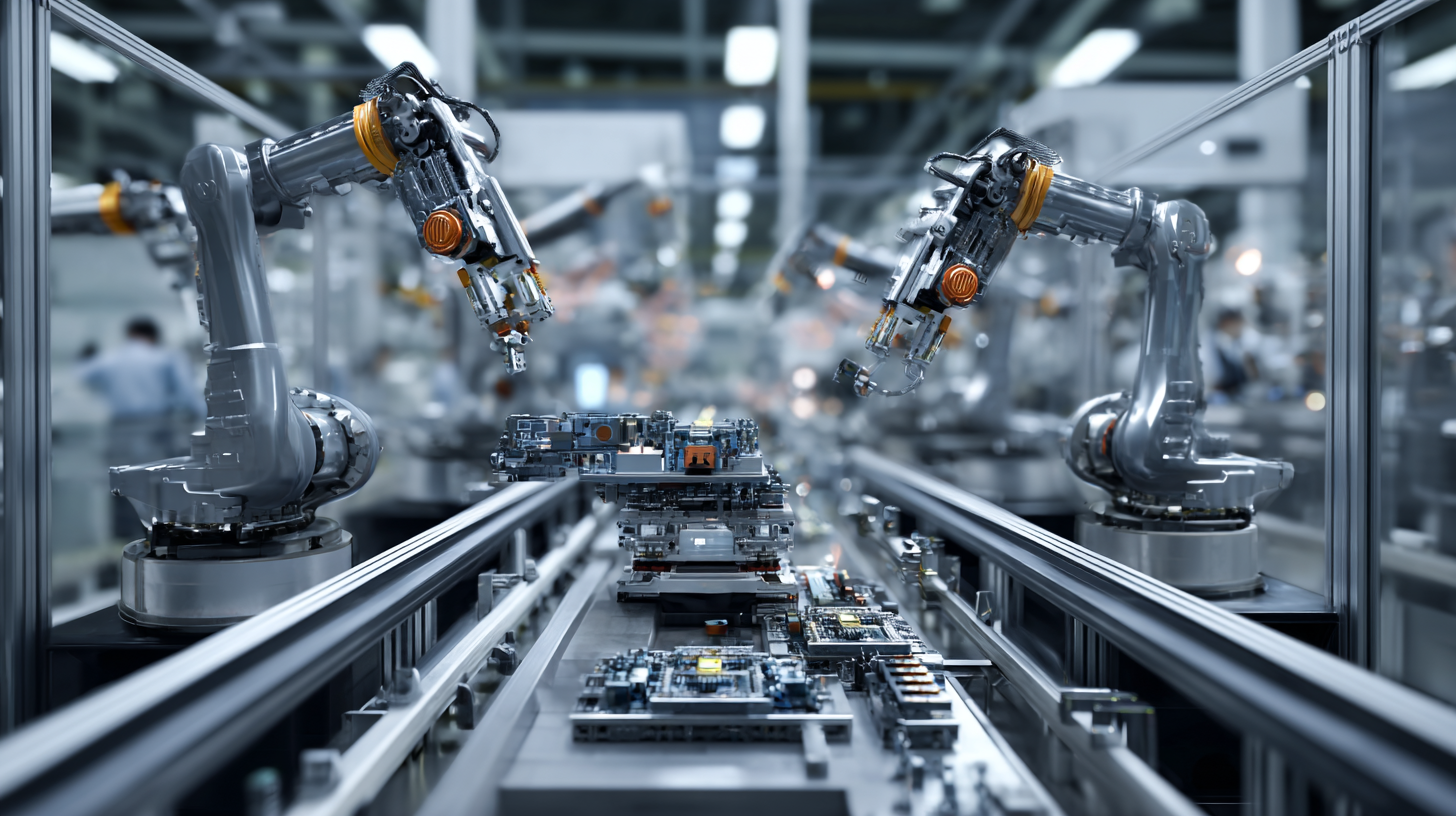

The landscape of modern industries is being transformed by a range of innovative automation technologies. Robotics has emerged as a cornerstone of manufacturing processes, enabling precision and efficiency that were previously unattainable. Advanced robots can operate alongside human workers, enhancing productivity while minimizing the risk of errors in tasks such as assembly and quality inspection. This collaboration not only streamlines workflows but also allows human operators to focus on more complex and creative aspects of production.

In addition to robotics, artificial intelligence (AI) plays a pivotal role in shaping the future of modern industries. By harnessing AI algorithms, companies can predict equipment failures, optimize supply chain logistics, and improve decision-making processes. Machine learning models analyze vast amounts of data to identify trends and enhance operational efficiency, making manufacturing systems more responsive and adaptable to changing market demands. Together, these automation technologies are redefining productivity standards and setting new benchmarks for success in the industrial sector.

The growing adoption of automation among top manufacturing firms reflects a significant shift in the industry towards efficiency and innovation. As companies face increased competition and rising consumer expectations, embracing automation technologies becomes crucial for maintaining a competitive edge. These firms are leveraging advanced robotics, artificial intelligence, and data analytics to streamline processes, reduce operational costs, and enhance product quality. This shift not only boosts productivity but also enables manufacturers to respond quickly to market changes and consumer demands.

Market trends demonstrate a clear inclination towards automated solutions, with leading manufacturing companies investing heavily in smart factories. Such environments integrate automation into every aspect of production, from supply chain logistics to final assembly. According to recent studies, firms that adopt automation report a notable decrease in production downtime and an increase in output, showcasing the tangible benefits of this technological transition. As automation continues to evolve, manufacturers are expected to further refine their processes, driving innovation and sustainability within the industry.

Manufacturing automation is increasingly recognized as a cornerstone of competitive advantage in modern industry. According to a report by McKinsey & Company, companies that integrate automation into their production processes can achieve productivity gains of up to 30%. This significant improvement arises from the ability of automated systems to operate continuously, minimizing downtime and maximizing output. Moreover, the World Economic Forum highlights that advanced manufacturing technologies, including robotics and AI-driven machines, can reduce production costs by a staggering 10-20%. This reduction directly enhances profitability and allows businesses to reinvest in innovation and market growth.

The return on investment (ROI) from automation is not just theoretical; it has tangible results in various sectors. A study conducted by the Boston Consulting Group shows that companies leveraging automation reported an average ROI of 300% over five years. These companies experience not only lower labor costs but also enhanced product quality and reduced defects, leading to higher customer satisfaction. Additionally, as industries face increasing pressure to remain agile and responsive to market changes, automation provides the flexibility needed to adjust production levels and switch product lines quickly, ultimately cementing its role as a vital element in achieving long-term industry success.