Manufacturing automation is reshaping industries worldwide. According to a recent report by MarketsandMarkets, the global manufacturing automation market is projected to reach $214 billion by 2026. This significant growth highlights the increasing adoption of automated technologies across various sectors.

Experts like Dr. Jane Smith, a leading researcher in automation technology, emphasize its transformative potential. She noted, “Manufacturing automation reduces human error and drastically improves efficiency." This statement captures the core benefits of automation, yet there are challenges to consider.

Many companies struggle with integration and upfront costs. Some processes may require a cultural shift within organizations. While manufacturing automation seems promising, businesses must address these hurdles to fully realize its benefits. The journey toward automation is complex, and consideration of both its advantages and drawbacks is crucial for ongoing innovation.

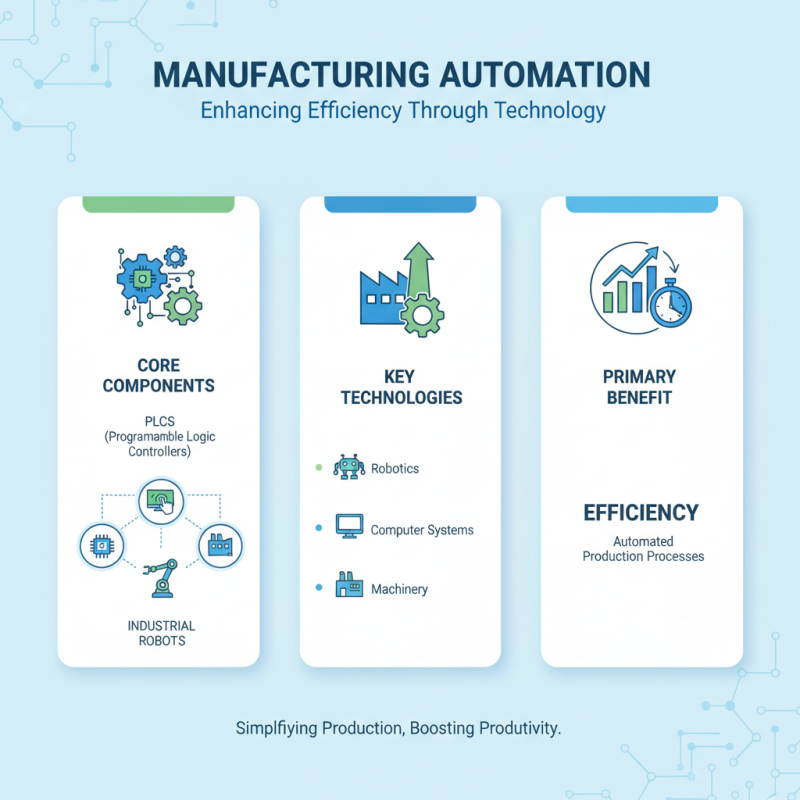

Manufacturing automation refers to the use of technology to automate production processes. This encompasses robotics, computer systems, and machinery. Its core components include programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial robots. Each element plays a vital role in enhancing efficiency.

According to industry reports, automation can increase production rates by up to 30%. It also improves product quality by minimizing human error. However, reliance on automation creates challenges. For example, system failures or cyber threats can disrupt operations. Moreover, not all jobs are safe; many workers face displacement as machines perform their tasks.

Investments in automation are significant, with estimates around $500 billion globally by 2025. Despite the advantages, companies must consider the balance between technology and workforce. The transition requires careful planning. It's crucial to focus on training and upskilling to avoid negative impacts on employment.

The evolution of manufacturing automation is both fascinating and complex. In the early days, factories relied heavily on manual labor. Workers performed repetitive tasks, which were time-consuming and often prone to errors. Over time, simple machines started to emerge, transforming the production landscape. The introduction of assembly lines in the early 20th century marked a significant milestone. This innovation allowed for quicker product output and reduced costs.

With the advent of electronics in the late 20th century, automation took a massive leap. Programmable logic controllers (PLCs) and robots began to take over monotonous tasks. However, not every industry embraced automation seamlessly. Some companies faced challenges, such as high initial costs and a need for specialized skills. These barriers highlighted the need for proper training and change management.

Tip: Embrace continuous learning to effectively integrate automation technologies. Understanding how these systems work can mitigate fear and resistance among employees.

The trend of industry 4.0 has further accelerated this journey. The use of IoT and AI is changing how manufacturers operate. Yet, the rush towards digital solutions presents concerns about cybersecurity and data privacy. Careful consideration is essential to address these challenges while leveraging automation's benefits.

Tip: Never underestimate the importance of a robust cybersecurity strategy in automation. Regular audits and employee training are key to safeguarding your systems.

Manufacturing automation is transforming modern industries significantly. One major benefit is improved efficiency. Automated systems perform repetitive tasks quickly and accurately. This reduces production time and lowers costs. For instance, robotic arms can assemble components much faster than human workers. They also maintain a consistent quality, which is essential in today’s competitive market.

Another key advantage is enhanced safety. Automation minimizes human exposure to hazardous environments. Factories can implement machines to handle dangerous tasks. For example, heavy lifting and toxic material handling can be fully automated. This shift not only protects workers but also reduces injury-related costs. However, there are challenges. Job displacement is a serious concern. Upskilling programs must be developed to help workers transition to new roles in an automated landscape.

Finally, flexibility is improved through automation. Businesses can quickly adjust production lines to meet changing demands. Yet, this requires a significant investment in technology and training. Companies need to reflect on whether they are ready for such change. The journey towards full automation can be complex, but the benefits often outweigh the challenges.

| Benefit | Description | Impact on Efficiency | Cost Savings |

|---|---|---|---|

| Increased Production Speed | Automation can significantly increase the speed of production processes. | High | Reduction in labor costs due to higher output. |

| Improved Quality Control | Automated systems offer consistent quality by minimizing human errors. | Moderate | Lower costs related to defects and rework. |

| Enhanced Safety | Automation reduces human involvement in hazardous tasks. | High | Savings from reduced accident-related expenses. |

| Flexibility and Scalability | Automated systems can be easily adjusted for different production needs. | Moderate | Ability to adapt quickly to market demands reduces downtime. |

| Data Collection and Analysis | Automation allows for real-time data collection, improving decision-making. | High | Data-driven improvements lead to strategic cost reductions. |

Implementing manufacturing automation can be challenging. One major concern is the initial investment. Reports indicate that companies often face costs ranging from $500,000 to several million dollars for automation technologies. Budget constraints can limit options. Additionally, the complexity of integration with existing systems can be overwhelming.

Workforce adaptation is another significant challenge. Employees may resist new technology. Training is essential, yet it requires time and resources. A survey found that nearly 70% of workers feel anxious about automation replacing their jobs. This anxiety can disrupt morale and productivity.

Tip: Invest in transparent communication about these changes. Involve employees early in the process. Encourage feedback to ease their concerns.

Another important consideration is the risk of over-automation. Companies may implement too many automated processes, leading to inefficiencies. Data from a 2023 industry analysis revealed that 36% of automation initiatives failed due to this issue. Balancing automation with human oversight is critical for success.

Tip: Continuously evaluate automated processes. Seek ways to maintain personal touch in operations. Personal interactions can enhance customer satisfaction.

This chart illustrates the impact of manufacturing automation on various dimensions within the industry. Notably, automation leads to a significant increase in productivity, reduction in costs, decreased error rates, and a positive effect on employee satisfaction. The percentages represent the estimated level of impact across these key areas.

Manufacturing automation is rapidly evolving.

A recent report predicts that by 2025, the global automation market will exceed $300 billion. This growth is driven by advances in AI and robotics. These technologies are changing how factories operate, reducing human error and improving efficiency.

However, the road to automation isn't without challenges. There is concern about job displacement. A study highlighted that 20 million manufacturing jobs could be lost by 2030 due to automation. Workers need reskilling to adapt to new roles. Industry leaders must focus on retraining their workforce to mitigate this impact.

Additionally, integrating new automation technologies can be costly. Many companies may struggle to update their existing systems. A survey found that nearly 60% of manufacturers view high initial costs as a major barrier to automation. Hence, finding a balance between investment and implementation is crucial for success. The future of manufacturing automation is bright, yet complex.