In 2023, the landscape of manufacturing is being dramatically reshaped by groundbreaking innovations in industrial automation. According to a recent report by MarketsandMarkets, the global industrial automation market is projected to reach $295.9 billion by 2026, growing at a CAGR of 9.2%. This surge underscores the critical role that automation technologies play in enhancing productivity, reducing operational costs, and improving product quality across various manufacturing sectors. As businesses increasingly embrace these advancements, the trajectory of the industry is set for significant transformation.

Industry expert Dr. Emily Chen, a leading voice in industrial automation, emphasizes the importance of adaptation: "Companies that fail to leverage industrial automation technologies will struggle to remain competitive in an increasingly fast-paced market." Her insights reflect a broader consensus among professionals who recognize that innovations such as artificial intelligence, machine learning, and robotics are not merely options but necessities for maintaining competitive advantage. This article highlights the top ten innovations in industrial automation that are revolutionizing manufacturing processes, showcasing how these advancements are redefining efficiency and effectiveness in operations.

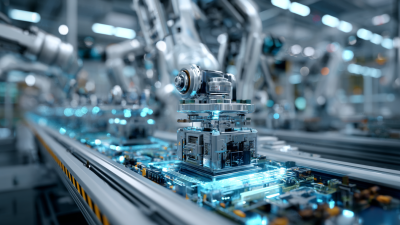

In 2023, the manufacturing landscape is significantly shaped by revolutionary robotics, which enhance both precision and efficiency. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record 486,000 units in 2022, a 25% increase from the previous year. This surge reflects manufacturers' growing investment in automation technologies to streamline production processes and minimize human error. Advanced robotics, equipped with AI and machine learning capabilities, allow for real-time data analysis, enabling manufacturers to optimize workflows and significantly reduce downtime.

Moreover, the integration of collaborative robots, or cobots, is transforming traditional manufacturing setups. A study by McKinsey & Company highlights that incorporating cobots can boost productivity by as much as 30% while enhancing worker safety. These robots work alongside humans, handling dangerous or repetitive tasks, which not only improves operational efficiency but also creates a more harmonious workplace environment. As companies continue to adopt these innovations, the impact of robotics on manufacturing is poised to grow, leading to greater competitiveness in the global market.

AI-powered predictive maintenance is revolutionizing the way manufacturers approach equipment management. By leveraging advanced algorithms and machine learning, companies can now predict when a machine is likely to fail, allowing them to schedule maintenance proactively. This shift from reactive to predictive maintenance minimizes unplanned downtime, which can be costly and disruptive. With real-time data analysis, organizations can monitor equipment health and performance, facilitating timely interventions before minor issues escalate into significant failures.

The benefits of AI-driven predictive maintenance extend beyond just improved uptime. Enhanced productivity and efficiency are key advantages, as manufacturers can optimize their maintenance schedules and allocate resources more effectively. By minimizing interruptions in production processes, companies are not only saving money but also improving their overall operational resilience. As the manufacturing landscape continues to evolve, the integration of AI technologies into maintenance practices will undoubtedly play a critical role in driving innovation and ensuring a competitive edge in the industry.

Smart sensors and the Internet of Things (IoT) are at the forefront of industrial automation innovations that are transforming manufacturing in 2023. These technologies enable machines to connect seamlessly, allowing for real-time data analytics and enhanced operational efficiency. As the industry continues to evolve, the integration of advanced IoT solutions helps manufacturers optimize their processes, minimize downtime, and improve product quality.

The rapid expansion of cellular IoT technology serves as a bridge between the physical and digital worlds, influencing various sectors. With the projected growth of IoT markets, particularly in logistics where smart containers are becoming increasingly prevalent, manufacturers are seizing the opportunity to leverage these innovations. By embracing AI-driven edge computing devices alongside IoT enhancements, companies can harness predictive maintenance capabilities, leading to reduced operational costs and enhanced decision-making based on actionable insights derived from real-time data analytics.

Collaborative automation is reshaping the landscape of manufacturing in 2023, marking a significant evolution in human-robot interaction. As companies seek to enhance productivity and efficiency, the integration of collaborative robots, or cobots, has surged. According to a report by the International Federation of Robotics, the deployment of collaborative robots is expected to increase by over 40% by the end of the year, underscoring their pivotal role in modern factories. This surge allows human workers to engage in more complex tasks while robots handle repetitive, mundane activities, resulting in a synergistic workflow that enhances operational efficiency.

Moreover, the safety and adaptability of collaborative robots have made them indispensable in various sectors. A study by McKinsey reveals that companies employing cobots experience a 30% reduction in operational costs due to improved safety protocols and increased output. The seamless interaction between humans and robots not only boosts productivity but also fosters a culture of innovation and adaptability within the workforce. With the ability to learn and adapt to different tasks, cobots are becoming essential partners in factories, driving the evolution toward more intelligent and flexible manufacturing processes.

The world of manufacturing is being rapidly transformed by advanced additive manufacturing technologies, particularly in the realm of 3D printing. This innovative approach has not only streamlined production processes but also introduced unprecedented flexibility and efficiency. The evolution of 3D printing, such as the emergence of new techniques like powder extrusion printing, is making it possible to create complex designs that were once deemed impossible with traditional manufacturing methods. As companies move towards scaling these technologies, we can expect significant reductions in production costs and time, fundamentally reshaping the industry landscape.

**Tips:** When considering the integration of 3D printing into your manufacturing processes, start by evaluating the specific needs of your production line. Identify areas where additive manufacturing could enhance efficiency or reduce waste. Collaborating with experts in the field can provide valuable insights into choosing the right materials and technologies suited for your applications.

Moreover, the rise of digitally-driven ecosystems, such as 3D printing farms, is demonstrating just how rapidly these innovations can be adopted. These facilities are designed to offer on-demand production capabilities, catering to diverse industry needs from aerospace to healthcare. As this technology continues to mature, businesses must stay ahead of the curve by continually assessing how these advancements can be leveraged for competitive advantage.

**Tips:** Keep an eye on market trends and emerging technologies related to additive manufacturing. Participating in industry conferences can also expose you to the latest innovations and networking opportunities with leaders in the field.