In the evolving landscape of manufacturing, conveyor belt automation has emerged as a critical component in enhancing operational efficiency and productivity. According to a recent report by the International Federation of Robotics, the global market for automation in manufacturing is expected to grow significantly, with conveyor systems playing a pivotal role in this transformation. As industries look to streamline processes and reduce labor costs, the integration of smart conveyor belt automation systems is increasingly recognized as a strategic investment.

Experts in the field, such as Dr. Emily Reynolds, a leading authority in industrial automation, underscore the importance of this technology. She states, “The future of manufacturing lies in the seamless integration of automation technologies, particularly within conveyor systems, which not only improve speed but also minimize human error.” With advancements in AI and IoT, manufacturers are now equipped to implement more sophisticated and adaptable conveyor belt automation solutions, thus enhancing both productivity and safety in the workplace.

As we explore the strategies for improving conveyor belt automation in the manufacturing process, it is crucial to consider not only the technological innovations but also the implications for workforce dynamics and operational costs. The pursuit of efficiency through automation is no longer a choice but a necessity for manufacturers aiming to remain competitive in a rapidly changing market.

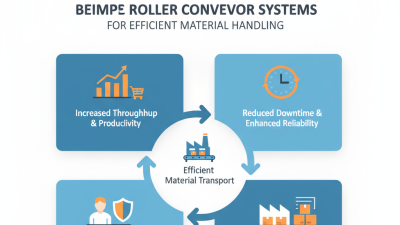

Conveyor belt automation plays a crucial role in enhancing the efficiency and productivity of manufacturing processes. By integrating automated conveyor systems, manufacturers can streamline the movement of materials and products, reducing the manual labor required and minimizing human error. Automation allows for a more consistent flow of goods, enabling operations to maintain an uninterrupted production cycle, which is essential for meeting demand and maintaining competitive edge in the market.

Understanding conveyor belt automation involves recognizing its various components and technologies, including sensors, control systems, and software. These elements work together to monitor the flow of materials, detect faults, and control the speed of the conveyor belts. By utilizing real-time data and analytics, manufacturers can optimize their production lines and make informed decisions to improve overall efficiency. Furthermore, advancements in machine learning and artificial intelligence are paving the way for smarter automation solutions, where conveyor systems can adapt and respond to varying production requirements dynamically, thus enhancing operational flexibility.

This chart illustrates the projected efficiency improvements in conveyor belt automation within manufacturing processes from 2021 to 2025. As technology advances, manufacturers anticipate significant gains in efficiency, reflecting a growing trend towards automation.

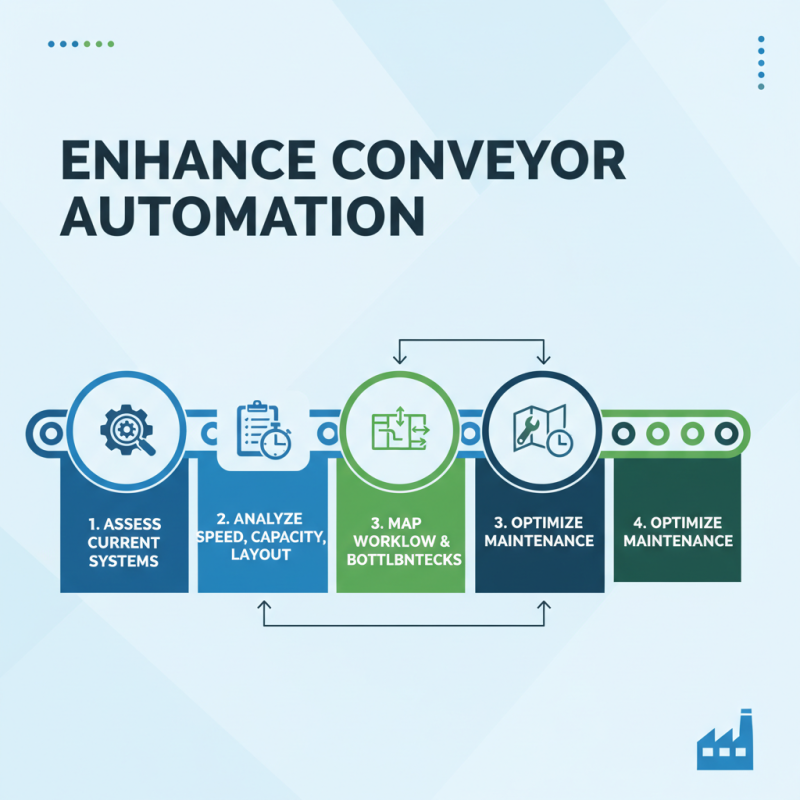

To enhance conveyor belt automation in the manufacturing process, the first step is to thoroughly assess the current conveyor systems in place. This involves a detailed analysis of the entire conveyor setup, including the speed, capacity, and layout. By mapping out the workflow and identifying each segment of the conveyor system, manufacturers can pinpoint specific areas that may be causing delays or bottlenecks. Regular maintenance schedules can also be evaluated to ensure that all components are functioning optimally, as wear and tear can significantly affect performance.

Once inefficiencies are identified, the next focus should be on developing targeted solutions. This could involve upgrading to more advanced technologies such as IoT sensors that monitor real-time performance and provide data analytics for predictive maintenance. Additionally, implementing automation software can optimize the flow of materials through the conveyor system, reducing manual intervention and increasing overall efficiency. Continuous training for staff on new systems and processes can further ensure that the workforce is equipped to maximize the efficacy of the updated conveyor operations.

Advancements in technology have fundamentally transformed the landscape of manufacturing, particularly in the realm of conveyor belt automation. By integrating IoT devices and machine learning algorithms, manufacturers can enhance their conveyor systems' efficiency and adaptability. IoT sensors can monitor real-time performance, detect anomalies, and facilitate predictive maintenance, thereby minimizing downtime and reducing operational costs. Machine learning can analyze vast amounts of operational data to optimize workflow, ensuring that conveyor belts operate at their peak performance levels throughout various stages of production.

Furthermore, the adoption of robotics and automated guided vehicles (AGVs) complements conveyor belt systems, creating a cohesive and agile manufacturing environment. These technologies can seamlessly transfer materials to and from conveyor belts, alleviating labor-intensive processes and speeding up production cycles. Enhanced vision systems can also be integrated into conveyor automation, allowing for real-time quality assurance checks, which ensure that products meet high standards before they reach the next phase of production. As these advanced technologies converge, they create a more connected and efficient manufacturing ecosystem, paving the way for future innovations in automation.

| Automation Technology | Implementation Cost ($) | Expected ROI (%) | Integration Time (Weeks) | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Automated Guided Vehicles (AGVs) | 50,000 | 25 | 10 | 6 |

| Conveyor Belt Sensors | 20,000 | 30 | 5 | 12 |

| IoT-Enabled Systems | 80,000 | 40 | 8 | 3 |

| Robotic Arms | 100,000 | 35 | 15 | 8 |

| AI-Powered Analytics | 60,000 | 45 | 6 | 4 |

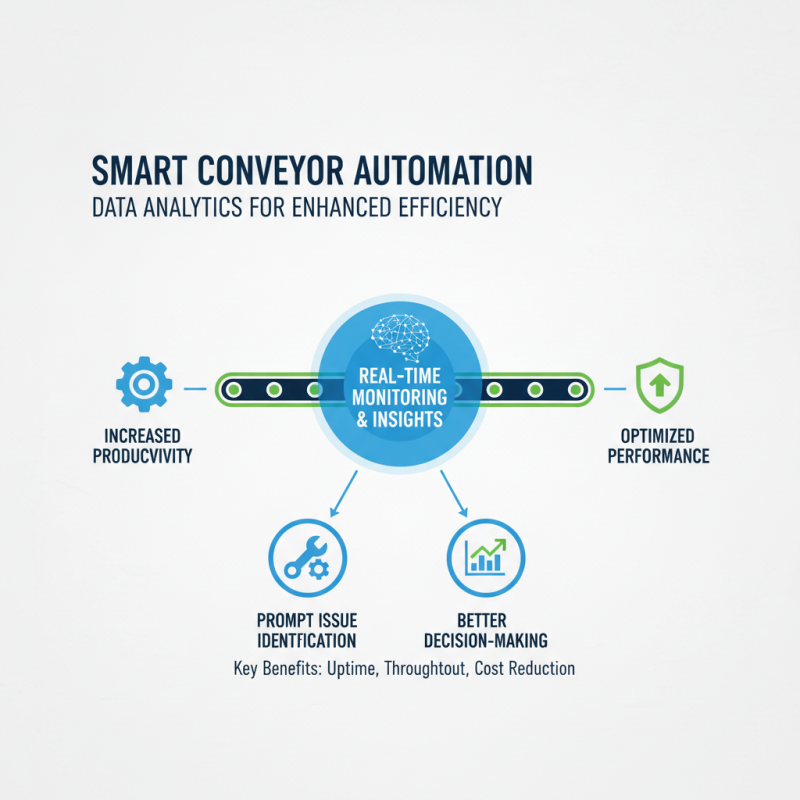

In today's manufacturing landscape, optimizing conveyor belt automation is crucial for enhancing efficiency and productivity. One of the most effective methods to achieve this is by implementing data analytics for real-time monitoring. By leveraging data analytics, manufacturers can gain insights into the operational performance of their conveyor systems, allowing for prompt identification of issues and enabling better decision-making processes.

Tips: Utilize sensors and IoT devices to gather data on conveyor belt speed, load weight, and operational interruptions. This data can guide maintenance schedules and reduce downtime, directly impacting throughput.

Moreover, real-time monitoring through data analytics enables predictive maintenance. Instead of rigid maintenance schedules, manufacturers can use data trends to anticipate equipment failures before they happen. This proactive approach not only extends the lifespan of the conveyor systems but also minimizes costly disruptions in production.

Tips: Implement anomaly detection algorithms to monitor data patterns and alert operators of any deviations, ensuring that issues can be addressed swiftly before escalating. Choosing the right analytics tools tailored to your specific manufacturing needs can significantly enhance the effectiveness of your automation strategy.

As manufacturing processes increasingly rely on automation, training the workforce becomes an essential factor in ensuring the effective use of automated systems. A well-trained team can significantly enhance the efficiency of conveyor belt automation, leading to smoother operations and reduced downtime. Employers must focus on equipping their employees with the necessary skills to adapt to new technologies, fostering an environment of continuous learning and growth.

To achieve this, companies should develop comprehensive training programs that encompass both theoretical knowledge and hands-on experience. Workshops, simulations, and on-the-job training can help workers gain confidence in utilizing automated systems. Providing resources such as manuals, online tutorials, and access to experienced mentors can further enhance the learning process.

By prioritizing workforce training, manufacturers can not only improve productivity but also create a culture of innovation where employees feel empowered to contribute to process improvements and problem-solving.