In today's competitive market, businesses must explore innovative solutions for efficiency. One key area to consider is packaging automation. It plays a crucial role in elevating productivity and reducing costs. Many companies are already embracing this technology to stay ahead.

Implementing packaging automation is not just a trend. It can transform how products are delivered to customers. However, it requires careful planning and consideration. Many businesses struggle with execution. They often overlook the need for proper training and support for staff. This oversight can lead to frustration and inefficiencies.

As you venture into packaging automation, remember it’s not a one-size-fits-all solution. Tailoring the approach to fit your specific needs is vital. Evaluating your current processes can reveal opportunities for improvement. Embracing this technology can yield significant benefits, but only if you understand its challenges. Balancing innovation and practical application is essential for success.

Packaging automation has become a key player in improving business efficiency. It refers to the use of technology to streamline the packaging process. According to a recent report, companies that adopt automation can see up to a 30% reduction in labor costs. This is significant for businesses looking to maximize their profitability while minimizing expenses.

The benefits of packaging automation extend beyond cost reduction. It enhances accuracy in packaging and minimizes errors. A survey from industry experts showed that automated systems can decrease product damage rates by up to 50%. However, companies may face challenges during the initial transition. Integrating new systems can disrupt existing workflows and require employee retraining. Addressing these potential setbacks is crucial for long-term success.

Investing in packaging automation can also improve speed. Automated machines can operate continuously, increasing output significantly. One study indicated that businesses using automation experienced a 25% boost in production rates. Still, it's essential to regularly evaluate the efficiency of these systems. Not every solution fits every business, and constant reassessment helps avoid stagnation.

Assessing your business needs for packaging automation is crucial. Start by evaluating your current processes. Are they efficient? Identify bottlenecks that delay production. This reflection will guide you in determining where automation can have the most impact.

**Tips**: Make a list of repetitive tasks. These are often excellent candidates for automation. Also, consider how many products you handle. If your volume is increasing, automation may be necessary to meet demand.

Think about your workforce. Are they overwhelmed? Automation can relieve pressure. However, it’s vital to communicate changes effectively. Involve your team in the planning process. Their insights can highlight potential challenges or improvements.

**Tips**: Host workshops to gather feedback. This fosters collaboration. It also helps in adapting to technology. Think about scalability too. Will your automated solution grow with your business? Adjust your plans accordingly.

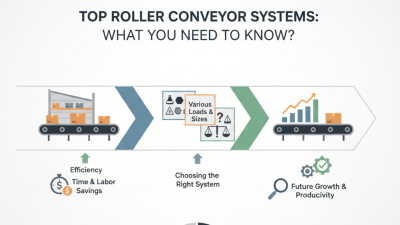

When considering packaging automation, selecting the right equipment is crucial. Various options exist, such as robotic arms, conveyor systems, and automated wrappers. Each type serves different needs. For instance, a robotic arm can handle delicate items, while a conveyor belt is ideal for high-speed packaging scenarios. Understanding your product's specific requirements can significantly influence your decision.

However, it's not a one-size-fits-all solution. A thorough analysis of your production volume, space, and budget is essential. Your team might face challenges in adapting to new technology. Training may be needed to ensure everyone is comfortable. Tracking the automation's performance can help identify what works and what doesn’t.

Investing time in research is beneficial. Gathering feedback from those who have implemented similar systems can offer valuable insights. Recognizing that initial costs may be high is part of the process. Automation should ultimately enhance efficiency and reduce errors, but it may take time to perfect the setup. Balancing innovation with practical concerns is essential for making the right choice.

Integrating packaging automation is crucial for success. Many businesses see tangible benefits when they effectively streamline their operations. Research shows that companies adopting automation can reduce packaging costs by up to 30%. This can significantly enhance profitability, especially in competitive markets.

Start by assessing current processes. Identify bottlenecks in packaging lines. Many companies overlook simple inefficiencies. They may find that manual processes slow down production. Consider employing automated machinery to handle repetitive tasks. This shift can free up employees for more strategic roles, enhancing morale and productivity.

However, challenges may arise during integration. Staff may resist change. Training is essential to ensure everyone is on board. Even with robust technology, errors in programming or setup can occur. Continuous monitoring will help refine the process. According to industry reports, ongoing adjustments can lead to a 20% improvement in line efficiency over time. Investing in automation is not without difficulties, but with thoughtful implementation, the rewards can be significant.

KPIs, or Key Performance Indicators, play a crucial role in measuring the success of packaging automation. Choosing the right KPIs can be challenging. It’s essential to align them with the overall business goals. Common KPIs include efficiency, waste reduction, and return on investment (ROI). Tracking these will help you see the impact of automation.

Efficiency metrics tell you how much product you can package in a given time. High efficiency means faster production. Waste reduction focuses on minimizing materials and energy used. This is vital for sustainability and cost control. ROI measures the financial benefits of automation versus its costs. It’s important to revisit these KPIs regularly.

However, there might be moments when results don’t meet expectations. Reflect on your processes and data analysis. Ask tough questions: Are we using the right technology? Is staff trained adequately? Such inquiries can lead to valuable insights. Automation is an evolving field, and continual reflection is necessary to truly measure success.