The Future of Precision Engineering with Best Flat Dies Laser Cutting Machines is a compelling topic as the demand for high-quality manufacturing continues to rise globally. According to a report by Mordor Intelligence, the laser cutting machine market is projected to grow at a CAGR of 6.78% from 2021 to 2026, driven by advancements in technology and an increasing need for precision in various industries. In this landscape, Flat Dies Laser Cutting Machines stand out due to their ability to deliver exceptional accuracy and efficiency, transforming how manufacturers approach intricate design tasks. With a focus on "Made in China, quality upgrade, bestselling globally", these machines not only enhance the production capabilities of manufacturers but also contribute to the overall shift towards smart manufacturing. As industries evolve, embracing such innovative solutions will be crucial for maintaining competitive advantage in the precision engineering sector.

The evolution of flat die laser cutting technology has revolutionized the precision engineering sector, allowing for unparalleled accuracy and efficiency in manufacturing. According to a recent report by MarketsandMarkets, the global laser cutting market is projected to reach $7.57 billion by 2026, growing at a CAGR of 6.2%. This growth can be attributed to advancements in laser technology, which have led to finer cutting capabilities and a reduction in material wastage. The introduction of fiber and disk lasers has notably enhanced cutting speeds and quality, making flat die laser cutting machines an essential tool in various industrial applications.

Incorporating these advanced laser cutting technologies allows manufacturers to achieve greater precision and adaptability in production processes. However, successful implementation requires understanding the operational nuances. For instance, selecting the appropriate laser type based on the material thickness can significantly impact cutting performance. It's vital to regularly maintain and calibrate machines to ensure optimal operation and prolong their lifespan.

Tip: When considering flat die laser cutting machines, invest in training for your operators. Proper knowledge of machine capabilities and maintenance can minimize downtime and enhance production efficiency. Additionally, always keep your cutting parameters updated to match the latest technology advancements to ensure the highest quality output.

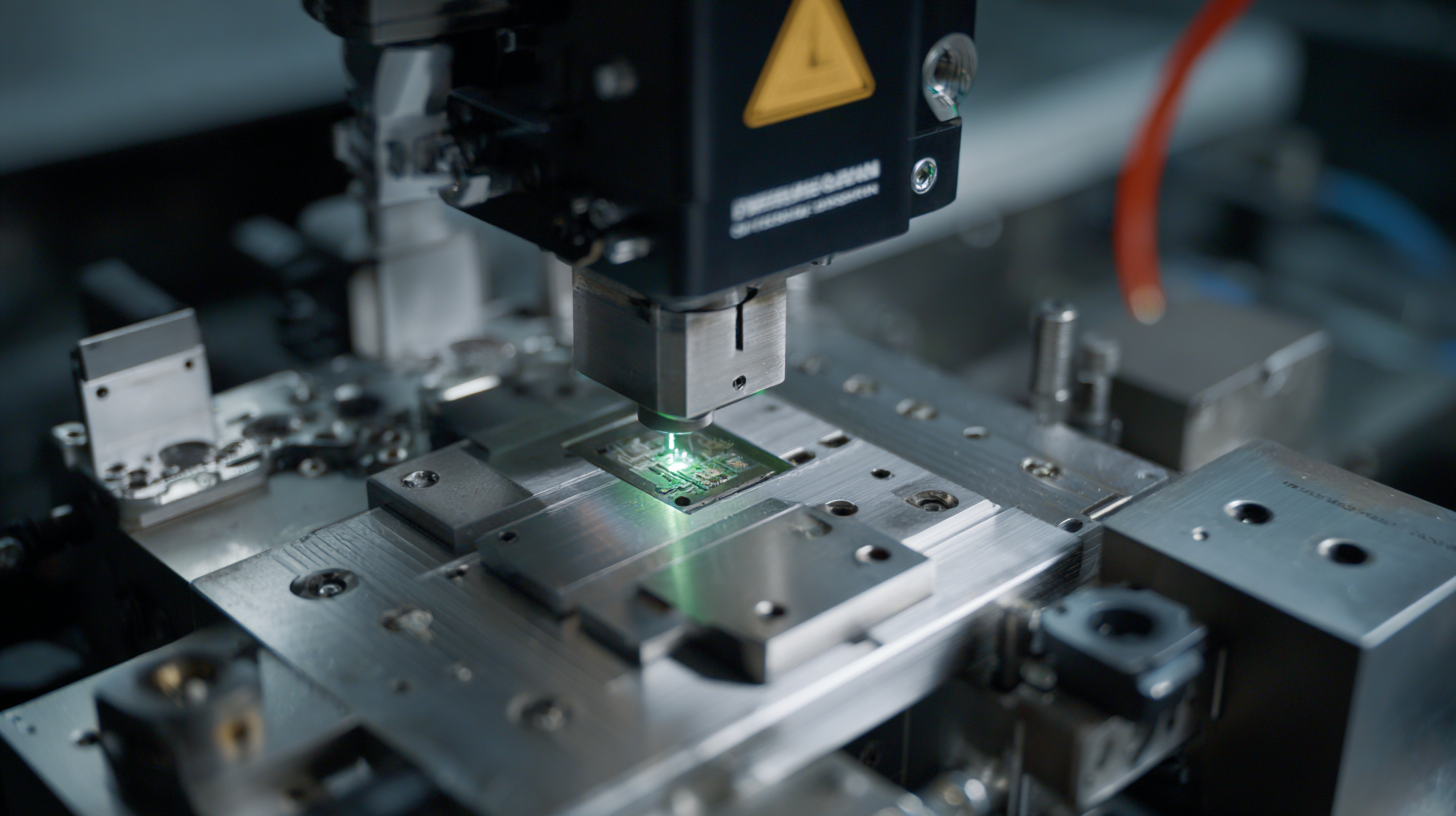

The advent of laser cutting machines has revolutionized precision engineering, offering several key advantages over traditional cutting methods. Firstly, laser cutting provides unparalleled accuracy and precision. Traditional methods often rely on mechanical blades that can wear down or deviate from their original paths, resulting in inconsistent cuts. In contrast, laser cutting uses focused beams of light to produce intricate designs and precise edges, ensuring that each piece meets stringent specifications. This level of detail is essential in industries such as aerospace, automotive, and electronics, where even the slightest imperfections can lead to significant issues.

Another significant benefit of laser cutting machines is their efficiency and speed. Unlike conventional methods that may require multiple passes or tooling changes, laser cutters can quickly adapt to various materials and thicknesses with minimal setup time. This adaptability reduces production time and waste, leading to cost savings and increased productivity. Additionally, the non-contact nature of laser cutting minimizes the risk of material deformation, as there is no physical tool pressure applied during the process. Overall, the integration of laser technology into precision engineering is setting a new standard for quality and efficiency, paving the way for innovative applications across multiple industries.

The precision engineering sector is poised for substantial growth, driven by the increasing demand for advanced technologies like laser cutting. The global laser processing equipment market is expected to expand from $28.51 billion in 2025 to $64.39 billion by 2032, representing a remarkable compound annual growth rate (CAGR) of 12.3%. This booming market is spurred by industries seeking precision in manufacturing processes, highlighting the increasing integration of laser technologies across various applications.

Additionally, the laser cutting machine market alone is projected to reach over $5.94 billion in 2023, with a CAGR of 7.6% from 2024 to 2032. This growth is attributed to advancements in laser technology and the rising need for precise cutting solutions across multiple sectors, including automotive and aerospace. As companies prioritize efficiency and accuracy in their manufacturing processes, laser cutting machines will play a crucial role in driving innovation and maintaining competitive advantage in the precision engineering landscape.

The precision engineering industry has witnessed a significant transformation with the implementation of flat die laser cutting machines. These advanced tools have enabled manufacturers to achieve unprecedented accuracy and efficiency in their operations. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from USD 4.13 billion in 2021 to USD 6.63 billion by 2026, showcasing a CAGR of 10.2%. This growth underscores the increasing reliance on cutting-edge technology to meet precise manufacturing demands.

Case studies from various industries illustrate the successful applications of flat die laser cutting. For example, in the automotive sector, a leading manufacturer reduced its material waste by over 30% after integrating flat die laser cutting into their production line. This machine not only provided enhanced cutting precision but also streamlined the overall workflow.

In the aerospace industry, another company utilized this technology to accelerate the production of intricate components, achieving a 25% increase in throughput while maintaining strict tolerances. These instances highlight how flat die laser cutting machines are not just an enhancement but a necessity in modern precision engineering.

The flat die laser cutting technology is on the brink of transformative innovations that promise to revolutionize precision engineering. As industries demand more complex designs with tighter tolerances, future advancements will likely focus on enhanced accuracy and efficiency. Emerging technologies, such as artificial intelligence and machine learning, can optimize cutting paths and predict material behavior, allowing for faster production cycles without compromising quality.

Moreover, the integration of advanced materials and improved laser sources will enable machines to cut through a wider variety of materials, increasing versatility. Innovations in software will also provide real-time monitoring and feedback systems, ensuring precision in every cut. As manufacturers strive for sustainability, eco-friendly practices will be increasingly adopted, such as minimizing waste through more precise cutting techniques and using renewable energy sources to power laser systems. All these factors contribute to the exciting future landscape of flat die laser cutting technology, making it an essential tool for the next generation of precision engineering.