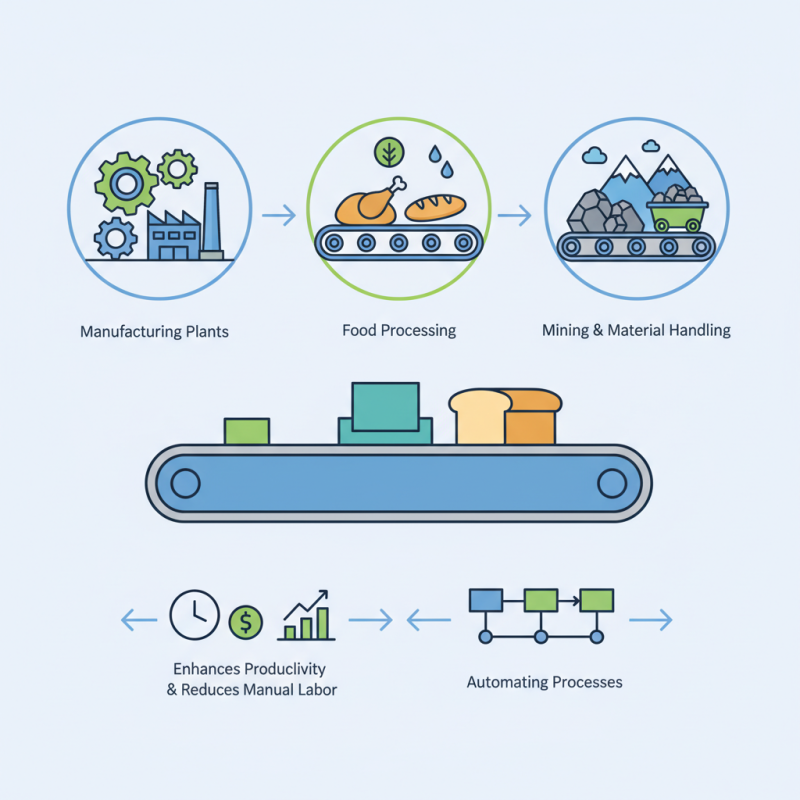

A conveyor belt is an essential component in modern industrial operations, facilitating the efficient movement of goods and materials across various sectors. This versatile technology is designed to transport heavy loads and streamline workflows, thereby enhancing productivity and reducing manual labor. From manufacturing plants to warehouses and distribution centers, conveyor belts have become indispensable in automating processes and ensuring that products move seamlessly through production lines.

In various industries, the design and function of conveyor belts can vary significantly to meet specific operational needs. For example, in food processing, conveyor belts are constructed with materials that comply with health and safety regulations to ensure hygiene while transporting edible products. In contrast, mining and material handling industries utilize rugged conveyor systems that can endure harsh conditions and transport bulky materials over long distances. By understanding the principles behind conveyor belts and their adaptation to different environments, businesses can optimize their operations and improve overall efficiency.

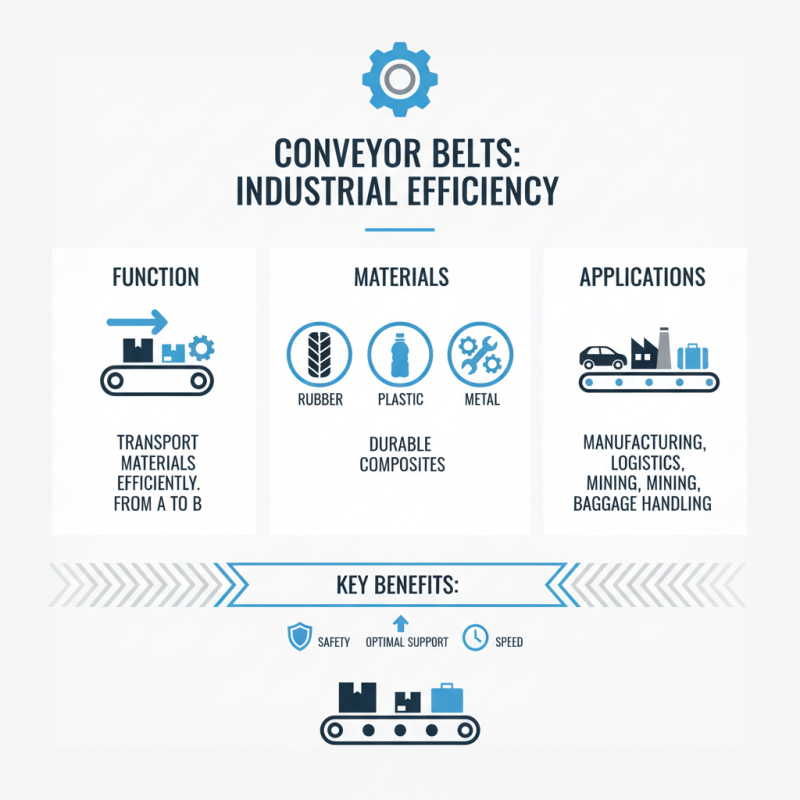

A conveyor belt is a vital mechanical component used in various industries to transport materials efficiently from one point to another. Typically made from durable materials like rubber, plastic, or metal, conveyor belts can handle a wide range of items, from heavy machinery parts to light packages. Their design varies based on the specific needs of different sectors, ensuring that they provide optimal functionality, support, and safety during material movement.

**Tips:** When selecting a conveyor belt for your industry, consider the weight and type of materials you will be transporting. It's crucial to choose a belt that not only supports the load but also withstands environmental conditions, such as temperature or moisture levels.

Furthermore, conveyor belts can be customized with various features, like adjustable speed, incline, and automatic sorting systems, enhancing productivity. Regular maintenance is also essential to ensure longevity and reliability. Monitoring for wear and tear can prevent unexpected downtime, maintaining the efficiency of operations across industries.

**Tips:** Implement a routine inspection and maintenance schedule for your conveyor system to identify potential issues early. This proactive approach can save costs and improve your overall operational efficiency.

Conveyor belts are essential components in various industries, facilitating the efficient movement of materials throughout production lines. Understanding the mechanics behind their operation reveals how they work in synergy with technology to optimize performance. Modern conveyor systems often integrate automated technologies, such as connected automated vehicles (CAVs), which enhance flexibility and efficiency in material handling. These systems are particularly beneficial in automotive assembly and end-of-line production, showcasing the adaptability of conveyor technology to meet industry demands.

Moreover, advancements in conveyor belt technology are continuously shaping the landscape of material transport. Innovative solutions, such as the integration of laser technology and deep learning for real-time monitoring, improve safety and operational efficiency. With the increasing reliance on conveyor systems in sectors like mining—where they transport materials over vast distances—mechanical innovations are crucial for adapting to dynamic conditions.

As industries evolve, the role of conveyor belts and their associated technologies will continue to expand, highlighting their significance in modern manufacturing and logistics.

Conveyor belts are essential components in various industries, designed to facilitate the movement of materials efficiently. Their design varies based on the specific requirements of each industry, leading to the development of several types of conveyor belts. The most common types include flat belts, modular belts, and bucket belts, each serving distinct purposes depending on the material being transported.

Flat belts are widely used for transporting light to medium-weight items across long distances. They consist of a single continuous loop and are ideal for assembly lines and warehouses. Modular belts, on the other hand, are made from interlocking pieces, allowing for flexibility in configuration and easier maintenance. These belts are excellent for handling products in food processing and packaging industries due to their hygiene standards. Lastly, bucket belts are designed for transporting bulk materials like grains or minerals vertically. They feature attached buckets that hold the material, making them perfect for applications involving steep inclines. Each type of conveyor belt plays a crucial role in streamlining operations and enhancing productivity in various sectors.

Conveyor belts play a crucial role across various industries, serving as fundamental components in the transportation of goods. In manufacturing, they enable the efficient movement of raw materials and finished products, reducing manual labor and increasing productivity. The food industry employs specialized conveyor belts that meet hygiene standards, transporting items like fruits, vegetables, and packaged goods from one processing stage to another. In warehousing and logistics, conveyor systems streamline the sorting and distribution of parcels, enhancing order fulfillment and delivery times.

Tips for maintaining conveyor belts include regularly checking for signs of wear and tear, ensuring proper alignment to avoid slippage, and keeping the belts clean to prevent contamination, especially in food sectors. Additionally, implementing routine inspections and timely replacements can significantly extend the life of the conveyor system.

In the mining sector, heavy-duty conveyor belts are essential for the transportation of raw materials, like coal and minerals, from underground to processing plants. Conveyor technology is also advancing with automation and smart tracking systems, allowing industries to monitor efficiency and optimize operations seamlessly. Such innovations continue to shape the future of material handling across diverse fields.

| Industry | Conveyor Belt Type | Material | Application |

|---|---|---|---|

| Manufacturing | Flat Belt Conveyor | Rubber | Assembly line transportation |

| Food Processing | Modular Belt Conveyor | Plastic | Food handling and packaging |

| Mining | Heavy-duty Conveyor | Steel | Material handling of ores |

| Logistics | Roller Bed Conveyor | Aluminum | Package distribution and sorting |

| Construction | Screw Conveyor | Steel | Transporting loose materials |

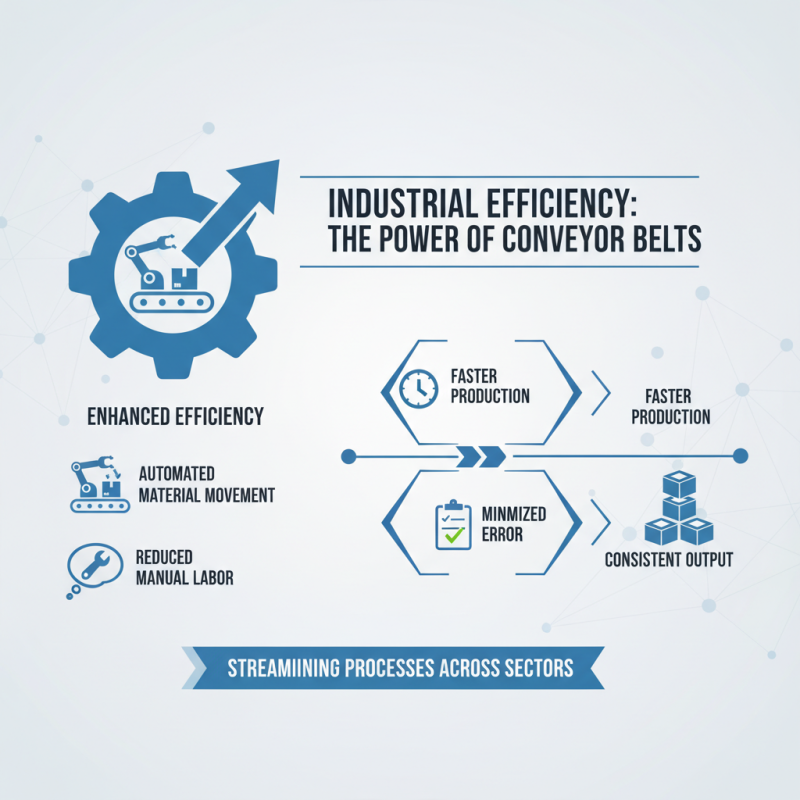

Conveyor belts play a crucial role in streamlining industrial processes across various sectors. One of the primary benefits of using conveyor belts is their ability to enhance efficiency. By automating the movement of materials, conveyor belts reduce the reliance on manual labor, allowing workers to focus on more complex tasks. This automation not only speeds up production times but also minimizes the risk of human error, leading to a more consistent output.

Additionally, conveyor belts improve safety in the workplace. With materials being transported automatically, the chances of accidents caused by lifting heavy items are significantly reduced. Conveyor systems can be designed to fit the specific layout of a facility, ensuring that the materials are moved securely and efficiently. Moreover, modern conveyor belts are often equipped with sensors that monitor the flow of materials and alert operators to any malfunctions, further enhancing safety and operational reliability. Overall, the integration of conveyor belts into industrial processes results in smoother operations, improved workplace safety, and increased productivity.