In today's competitive market, efficiency is key. A well-designed conveyor belt system can significantly enhance operational flow. According to industry expert John Smith, "A properly implemented conveyor belt system can transform the productivity of any manufacturing line." This highlights the importance of choosing the right system for your business.

Implementation of a conveyor belt system offers many benefits. It reduces manual handling and minimizes errors. Products move seamlessly from one station to another. Yet, some businesses hesitate. They worry about the initial investment or fear disruptions during installation. It's crucial to weigh these concerns against the potential gains in efficiency and cost savings.

Consider the application of a conveyor belt system in warehouse logistics. Imagine faster sorting of packages and quicker order fulfillment. However, it’s not without challenges. A poorly maintained system can lead to delays and frustration. Businesses must ensure regular checks and train staff adequately. This ongoing commitment can ultimately lead to a more efficient operation and a stronger bottom line.

Conveyor belt systems are essential in various industries. They streamline processes and enhance productivity. According to a report by the Conveyor Equipment Manufacturers Association, these systems can increase efficiency by up to 30%. Businesses save time and reduce labor costs with automated material handling.

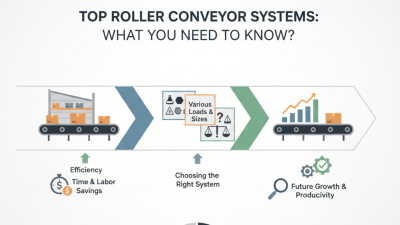

Understanding the functionality of these systems is crucial. Conveyor belts vary in design and material. Some are made for heavy loads, while others suit lighter items. A well-designed system can reduce product damage and improve workflow. However, not all systems fit every need. Companies must assess their specific requirements before implementation.

Proper maintenance is key to performance. Regular inspections can prevent breakdowns. Data shows 60% of conveyor failures result from neglect. Workers need training to handle equipment safely. Even a small misstep can lead to injuries or delays. Balancing efficiency and safety is a challenge. Careful planning is necessary to achieve optimal results.

| Feature | Description | Benefits | Typical Use Cases |

|---|---|---|---|

| Modularity | Flexible design for various layouts | Easily adapts to changing business needs | Manufacturing facilities |

| Speed Control | Adjustable speed settings | Increases efficiency in handling materials | Sortation and packaging |

| Durability | Built to withstand heavy loads | Lowers maintenance and replacement costs | Distribution centers |

| Customization | Tailored solutions for specific tasks | Improves productivity and workflow | Food processing, packaging |

| Safety Features | Incorporates guards and emergency stops | Reduces workplace accidents | Warehousing, construction |

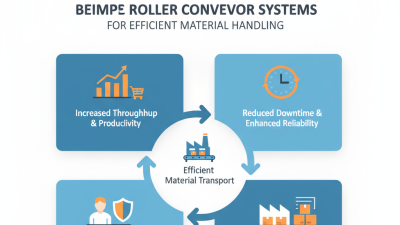

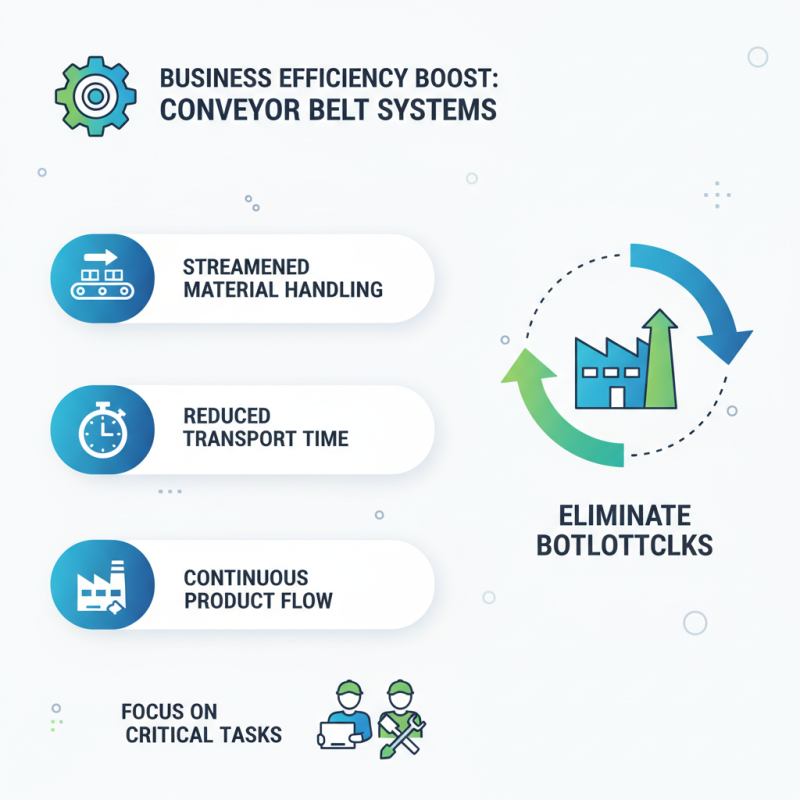

Implementing a conveyor belt system can significantly enhance business efficiency. These systems streamline material handling, reducing the time spent on transporting goods. With a continuous flow, products move smoothly from one location to another. This can help eliminate bottlenecks in production. Workers are then free to focus on other critical tasks.

Additionally, conveyor belts can improve safety in the workplace. They reduce the need for manual lifting and carrying. This can lead to fewer injuries and a more comfortable work environment. However, maintenance is vital. Neglecting regular checks can cause breakdowns, halting operations. A well-maintained system, though, can last for years.

Cost-effectiveness is another advantage. While the initial investment may be significant, the return often justifies it. Over time, savings on labor and efficiency improvements can be substantial. Yet, every business is unique. It’s important to assess whether such a system fits your specific operational needs. Carefully analyzing workflow can help determine the right solution.

When selecting a conveyor belt system, several factors deserve attention. The type of materials being handled is essential. Different materials may require specific belt materials to prevent damage and ensure efficiency. Consider the load capacity as well. It’s crucial to choose a system that can accommodate your heaviest loads without compromising performance.

Design layout is also vital. Think about how your facility's space flows. A well-planned layout can minimize downtime and enhance productivity. Poorly placed systems cause congestion. This leads to inefficiencies and potential safety hazards.

Tips: Evaluate your current workflow before making a decision. This evaluation helps identify bottlenecks. Also, involve your employees in the selection process. They understand daily operations better. Their insights can lead to better choices.

Don't overlook maintenance requirements. Some systems might save costs upfront but increase long-term expenses due to high maintenance. Make sure you understand the maintenance needs of your chosen system. Balancing cost and functionality is key for sustainable efficiency in your business.

Conveyor belt systems have gained popularity for their efficiency in material handling. They outperform traditional methods like manual labor and forklifts in speed. For many businesses, automation saves time and reduces human error. Conveyor belts streamline the movement of goods across facilities.

Tip: Evaluate your space before choosing a conveyor system. Make sure it fits well into your layout. You want to avoid overcrowding.

Comparing these systems to other solutions reveals distinct advantages. Unlike manual handling, conveyor belts reduce physical strain on workers. They can also run continuously. However, installation costs can be high. Businesses should weigh these costs against long-term benefits.

Tip: Always consider maintenance. Look for systems that are easy to clean and repair. A complicated setup may lead to increased downtime.

Maintaining conveyor belt systems is critical for business efficiency. Studies show that regular maintenance can extend the lifespan of these systems by up to 50%. With proper care, conveyor belts can operate smoothly for 10 to 15 years. However, neglect leads to costly downtime. In fact, industry reports indicate that unplanned maintenance can increase operational costs by 20%.

One key practice is to conduct regular inspections. Check for wear and tear. Pay attention to the tracking of the belt and rollers. Even small misalignments can cause significant issues. Routine lubrication is vital too. It reduces friction and wear. According to the U.S. Department of Energy, well-lubricated systems can save up to 5-10% in energy costs.

Yet, some companies overlook employee training. Skilled workers are essential for effective maintenance. A lack of knowledge can result in improper handling. This can lead to faster degradation of the system. Investing in training can yield a return of four times the initial cost. The dividends of a well-maintained conveyor belt system are clear, but the commitment to upkeep must be equally strong.

This bar chart represents the efficiency improvements in different industries after implementing conveyor belt systems. The data showcases percentage increases in operational efficiency based on industry research.