In the ever-evolving field of packaging, the efficiency of production lines hinges on the choice of equipment. The 2026 Best Case Packer Options highlight the need for businesses to adapt to rising demands. According to a recent industry report by Smith Packaging Insights, the market for case packers is projected to grow by 7.5% annually over the next five years.

Experts believe that investing in advanced case packer technology can significantly enhance productivity. John Davis, a leading consultant in packaging automation, noted, "Choosing the right case packer can reduce labor costs and minimize errors.” This insight emphasizes a crucial point: not all case packers are created equal. Businesses must analyze their specific needs carefully.

However, finding the ideal case packer presents challenges. Companies may face high initial costs and technical complexities. Manufacturers must consider these factors while aiming for efficient solutions. The decision-making process should incorporate long-term benefits, beyond immediate expenses. The 2026 guidance on case packers will assist in navigating these hurdles effectively.

Case packing techniques play a crucial role in the packaging industry. They determine how products are bundled for storage and transportation. An efficient case packing solution maximizes space while minimizing the risk of damage. This balance is essential for reducing costs and improving supply chain efficiency.

There are various techniques to consider. Some involve intricate designs that enhance stability. Others focus on speed, aiming to increase throughput. However, not every method suits every product. Assessing the specific needs of the items is vital. Companies sometimes overlook this step, leading to inefficiencies or increased waste.

Automation in case packing has transformed the landscape. Machines can pack faster and more accurately than manual labor. Yet, there may be a learning curve. Employees must adapt to new technologies and processes. Communication among teams is essential. A lack of coordination can result in operational hiccups. Ultimately, the best case packing option will depend on balancing these factors.

| Technique | Speed (cases/min) | Efficiency (%) | Flexibility (Product Types) | Investment Cost (USD) | Maintenance Requirement |

|---|---|---|---|---|---|

| Robotic Case Packing | 25 | 90 | Bottles, Boxes, Trays | 50,000 | Low |

| Gravity Case Packing | 15 | 85 | Cans, Jars | 30,000 | Medium |

| Semi-Automatic Case Packing | 10 | 80 | Bagged Products, Loose Items | 20,000 | High |

| Automatic Case Packing | 30 | 95 | Various Shapes and Sizes | 75,000 | Low |

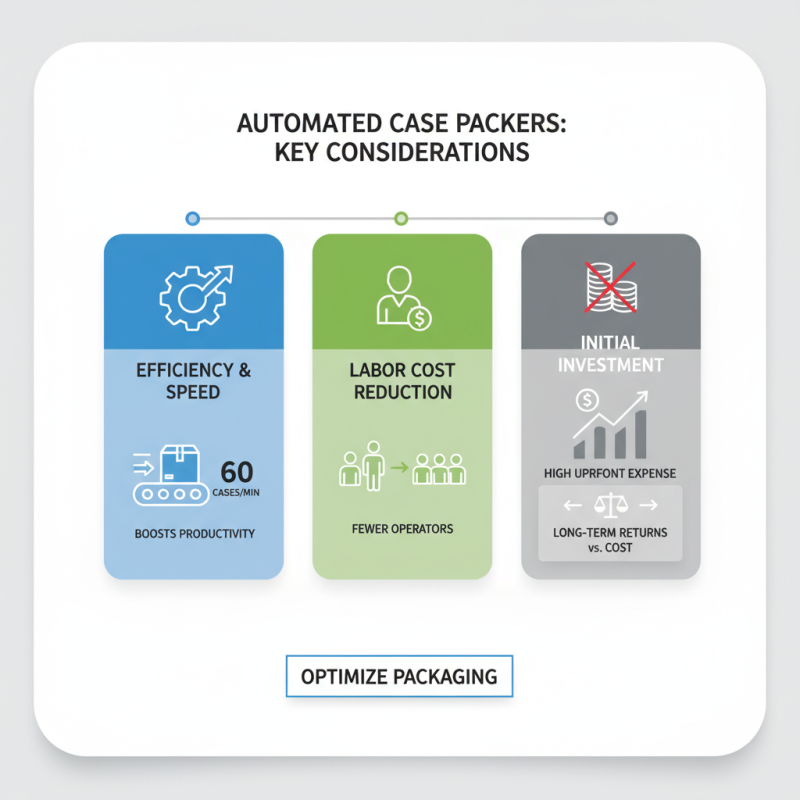

When considering packaging solutions, case packers play a pivotal role. Automatic systems are highly efficient, capable of handling up to 60 cases per minute. This speed significantly boosts productivity. Companies can reduce labor costs as fewer operators are needed. However, the high initial investment often poses challenges. Businesses must weigh long-term returns against upfront expenses.

Semi-automatic systems offer flexibility and lower costs. Typically, they require more manual intervention, making them less efficient than fully automated counterparts. Reports indicate that semi-automatic systems can handle 20 to 30 cases per minute. They are ideal for smaller production runs or companies experiencing fluctuating demand. Yet, relying heavily on manual labor leads to increased variability and potential errors.

In the growing market, understanding the balance between automation and manual processes is critical. Investing in a system should align with production goals and budget constraints. Continuous evaluation of efficiency helps identify when an upgrade is needed. The choice between automatic and semi-automatic systems isn't always clear-cut. It demands careful consideration and strategic planning for optimal results.

When selecting a case packer, consider the efficiency of your operations. Speed is crucial. A faster packer reduces labor costs and improves productivity. Look for models that allow for quick changeovers. This can save you time when switching between products.

Think about the type of packaging you use. Some case packers work better with specific materials, like cardboard or plastic. Evaluate your needs before making a decision. Also, consider the size of your product. Packer versatility matters. A machine that adjusts for different sizes can adapt to your growing business.

Tips: Test different models before purchasing. Look for features that enhance user experience. A user-friendly interface can lead to fewer mistakes. Training staff on how to operate new machinery is vital. Always keep maintenance in mind. Regular checks help prevent breakdowns. This saves time and money, ensuring smooth operations.

Efficiency in case packing is crucial for optimizing the packaging process. Companies often assess machinery based on key performance metrics. Speed, flexibility, and reliability are vital indicators. Many machines can pack boxes quickly. However, they may struggle with varying box sizes or shapes. This limitation can slow down production.

Another important aspect is the ease of operation. Machines should be user-friendly, requiring minimal training. Complicated systems can lead to errors and delays. Maintenance is also critical. Regular upkeep ensures machines run smoothly. Neglecting this can result in unexpected downtimes.

Data collection plays a significant role in performance analysis. Companies should track packing speed and error rates. This information helps identify patterns and areas for improvement. However, relying solely on data can be misleading. Human oversight is necessary to interpret the results accurately. Balancing technology and human skill is key to achieving optimal performance.

When considering case packers for 2026, a few models stand out. Efficiency is key in packaging. Some models offer automated solutions that enhance speed. However, they may have a learning curve. Training staff can take time. This factor is often overlooked.

Some machines are compact but powerful. They can fit into smaller spaces, which is useful for limited floor plans. Yet, their size might limit their capacity. Businesses must assess their needs carefully. Other models, while larger, can handle higher volumes. They may require more maintenance, which could add costs.

User reviews often highlight durability. Some machines perform well under pressure. However, occasional breakdowns can disrupt productivity. It's crucial for users to weigh these considerations. Identifying the right balance is essential for efficient packaging solutions in a competitive market.