In today's fast-paced manufacturing environment, efficiency is crucial. Case packer machines play an essential role in automating packaging processes. These machines reduce labor costs and increase productivity. They ensure products are securely packed for shipping. This efficiency leads to satisfied customers and fewer returns.

However, finding the best case packer can be challenging. The market offers various options, each with unique features. It’s important to consider factors like speed, size, and affordability. Some businesses may struggle to choose the right model. Not every machine fits every production line. Therefore, assessing individual needs becomes vital.

Investing in a case packer is not a one-size-fits-all solution. Companies must weigh the benefits against their specific requirements. They should also reflect on long-term goals. The choice can significantly impact the overall workflow. In this article, we will explore the top 10 best case packer machines available. Each of these machines promises efficient packaging solutions tailored to diverse needs.

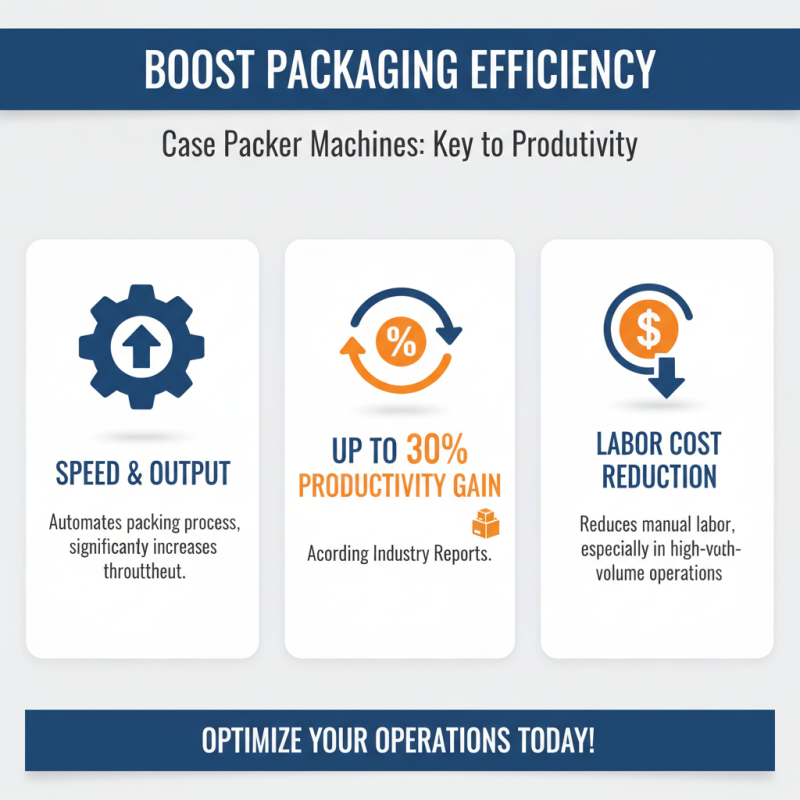

In the packaging industry, efficiency is key. Case packer machines play an essential role in speeding up the packing process. According to recent industry reports, businesses can improve productivity by up to 30% with the right equipment. A well-designed case packer can significantly reduce labor costs, especially in high-volume operations.

Selecting the right packing machine can be challenging. Efficiency metrics such as packing speed and accuracy are crucial. For instance, some machines can pack up to 20 cases per minute. Others may vary depending on the product size and complexity. This variability reminds us that not every solution fits all needs.

Tips for success: Always analyze your workflow. Identify bottlenecks that could be addressed by automation. Consider a trial run for new machines before committing. Also, ensure your team is trained on these technologies. This helps in maximizing the profitability of your investment and maintaining quality throughout the packaging process.

When evaluating case packer machines, several key features stand out. Speed is essential; higher speeds mean more efficient operation. However, too much speed can lead to errors. Machines must strike a balance. A machine that can handle various box sizes adds versatility. Flexibility in packaging styles is also beneficial. The ability to switch between different formats without extensive downtime is a significant advantage.

Another important factor is ease of operation. Complex machines can lead to human error. Interfaces should be user-friendly, allowing operators to train easily. Maintenance is crucial as well. Machines require regular checks to ensure optimal performance. Neglecting this can lead to costly downtime. Energy consumption is another consideration. Efficient machines save costs in the long run. However, finding the most energy-efficient option may require thorough investigation.

Finally, integration with existing systems is vital. The machine should seamlessly fit into your current workflow. Compatibility issues can cause disruptions, which nobody wants. Reflecting on these considerations can improve the selection process. The right case packer machine can enhance productivity significantly. However, overlooking even one feature can hinder overall efficiency.

This chart illustrates the performance assessment of the top 10 case packer machines based on efficiency and speed metrics. The data reflects the average cases packed per hour (CPH) and the operational efficiency percentage of each machine.

Case packers are essential in modern packaging lines. They greatly affect the overall efficiency of production. According to industry reports, nearly 30% of packaging time can be saved by using automated solutions. Different models vary in their automation levels, impacting their speed and adaptability.

Advanced models feature integrated robotics. This allows for real-time adjustments based on product dimensions. They can handle multiple case sizes without significant downtime. However, simpler machines with lower automation require manual adjustments, leading to inefficiencies. A recent analysis highlighted that 40% of manufacturers still use semi-automated devices, which may hinder their competitiveness.

Maintenance remains a concern. Fully automated systems can require specialized knowledge for repairs. Meanwhile, lesser automated designs may be more accessible but could lead to longer operational delays. Business leaders often wrestle with balancing upfront costs and long-term savings. Thus, choosing the right case packer involves comprehensive evaluation.

| Model | Automation Level | Speed (Cases/min) | Dimensions (LxWxH cm) | Weight (kg) | Power Consumption (kW) |

|---|---|---|---|---|---|

| Model A | Fully Automated | 40 | 200 x 150 x 180 | 800 | 5.5 |

| Model B | Semi-Automated | 30 | 180 x 140 x 160 | 600 | 4.0 |

| Model C | Fully Automated | 50 | 210 x 160 x 190 | 850 | 6.0 |

| Model D | Manual | 10 | 150 x 120 x 140 | 400 | 3.0 |

| Model E | Semi-Automated | 25 | 160 x 130 x 150 | 500 | 3.5 |

| Model F | Fully Automated | 45 | 220 x 170 x 200 | 900 | 6.5 |

| Model G | Semi-Automated | 20 | 140 x 110 x 130 | 350 | 2.5 |

| Model H | Fully Automated | 55 | 230 x 180 x 210 | 950 | 7.0 |

| Model I | Manual | 15 | 170 x 140 x 160 | 600 | 3.0 |

| Model J | Semi-Automated | 35 | 200 x 150 x 180 | 750 | 5.0 |

Investing in case packer technology can significantly enhance operational efficiency. The right machines can automate packaging processes. This often results in reduced labor costs and higher output. However, businesses should weigh these benefits against initial investment costs.

When considering a purchase, analyze your production volume. A high-volume setting may justify the cost. In contrast, smaller operations might find it challenging to break even. Evaluate the long-term return on investment. It’s crucial to ensure that the technology aligns with your production goals.

**Tip:** Regularly assess machine performance and maintenance needs. This ensures you avoid unexpected downtimes and repairs that can affect productivity.

Another consideration is staff adaptation. Employees may require training to operate new machines effectively. Resistance to change can lead to inefficiencies. Thus, open communication about the benefits of new technology is vital.

**Tip:** Involve your team in the selection process. Their insights can lead to better choices and smoother implementation.

The packaging industry is undergoing a significant transformation. Companies are increasingly focusing on sustainable practices. According to the “Sustainable Packaging Market” report by Smithers, the global market for sustainable packaging is projected to reach $500 billion by 2028. This shift reflects a growing consumer demand for greener options. Brand loyalty is often influenced by sustainable packaging choices.

Integrating eco-friendly materials is vital. Many companies are exploring biodegradable options. Innovations such as mushroom-based packaging and recycled plastics are on the rise. However, implementing green solutions can be challenging. The cost of sustainable materials is considerably higher than traditional options. Firms must balance sustainability with profitability.

Tip: Evaluate your packaging processes for waste reduction. Small changes can lead to big savings.

Adopting energy-efficient equipment is another trend. Efficient case packer machines can minimize energy consumption. However, many businesses hesitate to invest in new technology. The upfront costs deter them. It's essential to weigh the long-term benefits.

Tip: Research available grants for sustainable upgrades. They can ease the financial burden.

As the industry evolves, staying informed is crucial. Examining market trends helps navigate the shifting landscape. Focusing on sustainability is not just a trend; it is becoming a necessity for businesses.