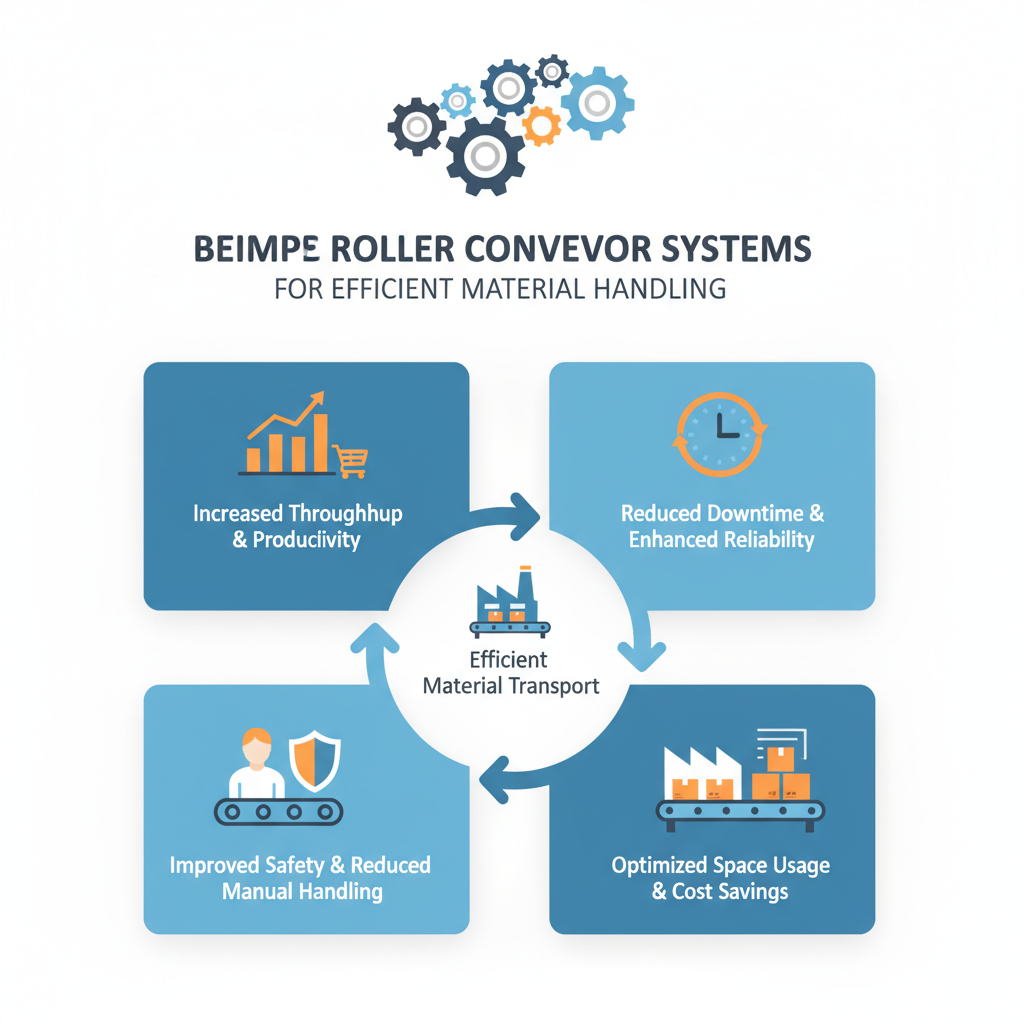

In the fast-paced world of modern logistics and material handling, the efficiency of operations is paramount. Roller conveyor systems have emerged as vital components in enhancing productivity and streamlining processes across various industries. According to a 2022 report by the Material Handling Industry of America (MHIA), over 70% of companies have adopted automated solutions like roller conveyor systems to improve workflow and reduce manual handling costs. This statistic underscores the growing reliance on technology-driven solutions in achieving operational excellence.

Experts in the field, such as Dr. Robert Chen, a leading authority on material handling systems, emphasize the transformative impact of roller conveyor systems. "The integration of roller conveyor systems not only boosts throughput but also minimizes downtime, which is essential in today's competitive environment," Dr. Chen states. His insights highlight the crucial role that roller conveyor systems play in facilitating efficient material transport, ultimately aiding businesses in meeting the increasing demands of consumers.

As industries continue to evolve, the adoption of roller conveyor systems is a strategic move that can yield significant benefits. From reducing labor costs to enhancing safety and optimizing space usage, the advantages are clear. With further advancements in technology, roller conveyor systems will likely become even more integral to successful material handling strategies in the coming years.

Roller conveyor systems have become an essential component in modern material handling processes, enhancing efficiency across various industries. By utilizing a series of rollers mounted on frames, these systems allow for the smooth transfer of goods, significantly reducing manual labor. According to a report by the Material Handling Industry of America, over 60% of warehouses have integrated conveyor systems to optimize their operations and streamline logistics.

The versatility of roller conveyors is one of their greatest advantages. They can handle a wide range of materials, including boxes, crates, and pallets, making them suitable for environments that require diverse product handling. Furthermore, research from the Conveyor Equipment Manufacturers Association has shown that incorporating roller conveyors can boost operational efficiency by up to 25% by minimizing handling time and maximizing throughput.

Tips: When implementing roller conveyor systems, it’s crucial to assess the specific needs of your operation. Consider factors such as load capacity, speed requirements, and space constraints. Regular maintenance checks can also prevent breakdowns and ensure the longevity of the system. By staying informed about technological advancements and best practices, businesses can continue to enhance their material handling strategies effectively.

Roller conveyor systems have become a cornerstone of efficient material handling in various industries. Their design simplicity allows for seamless integration into existing workflows, significantly enhancing operational efficiency. Key features such as adjustable speed controls, variable roller spacing, and durability contribute to their versatility and effectiveness. With adjustable speed controls, companies can optimize the flow of materials based on different staging requirements, reducing downtime and improving throughput.

Tips for increasing the efficiency of roller conveyors include regularly maintaining the system and keeping the rollers clean. Dust and debris can significantly impede performance, so implementing a routine cleaning schedule can prevent maintenance issues. Additionally, consider the layout of your roller conveyor system to ensure minimal obstructions and smooth transitions between different sections. This not only speeds up the movement of goods but also enhances worker safety by minimizing the risk of accidents in congested areas.

Another enhancing feature is the ability to customize roller configurations. Choosing between different roller diameters and materials can cater to specific load types, ensuring optimal handling for delicate or heavy items. This tailored approach can maximize efficiency while prolonging the lifespan of the conveyor system. Regularly reviewing material handling needs can lead to better-informed decisions when upgrading or reconfiguring roller conveyors to meet evolving demands.

Roller conveyor systems have become a cornerstone in the field of efficient material handling, particularly in reducing labor costs.

According to a report by the Material Handling Industry of America, implementing conveyor systems can lead to labor cost reductions of up to 30%.

This is largely due to the automation of transporting materials, allowing employees to focus on more strategic tasks rather than manual handling.

In high-volume operations, roller conveyors can facilitate smoother flow and reduce the need for forklift operations, which are often resource-intensive and costly.

In addition to labor cost savings, roller conveyors enhance productivity by minimizing product handling times.

A study by the Warehouse Education and Research Council (WERC) indicates that the integration of roller conveyor systems can improve throughput by as much as 50%.

This increased efficiency not only helps in meeting tight deadlines but also optimizes space utilization within the facility, leading to further cost savings.

Tips: When considering roller conveyor systems for your operation, assess the layout of your facility to maximize efficiency.

Choose conveyors with adjustable speeds to accommodate different types of products.

Regular maintenance checks can also ensure longevity and prevent costly downtimes, further enhancing your return on investment.

Roller conveyor systems have a significant impact on warehouse productivity by streamlining material handling processes. By utilizing gravity and motorized conveyors, these systems facilitate the efficient movement of goods, reducing manual labor and minimizing operational delays. According to a recent industry report, the global roller conveyor market is projected to grow at a CAGR of 4.5% through 2027, indicating increasing recognition of the benefits these systems provide in enhancing workflow efficiency and reducing operational costs.

The deployment of roller conveyor systems can substantially improve workflow efficiency in warehouses. They minimize bottlenecks by providing continuous flow and easy transfer of goods, especially in loading and unloading operations. A study highlighted that warehouses equipped with automated and semi-automated roller conveyors report up to a 25% increase in throughput compared to manual systems. Furthermore, the integration of these systems can lead to a reduction in labor costs, with companies saving an estimated 15-20% per year on operational expenses, which can be redirected towards further innovations in supply chain management.

| Benefit | Description | Impact on Productivity |

|---|---|---|

| Increased Efficiency | Roller conveyors allow for continuous movement of materials, reducing handling time. | Reduces overall cycle times by 20%. |

| Cost Savings | Minimizing labor costs due to reduced manual handling. | Can save up to 30% on labor expenses. |

| Enhanced Safety | Reduces the risk of employee injuries linked to heavy lifting. | Increases safety compliance by 15%. |

| Flexible Configuration | Can be configured to fit various warehouse layouts and needs. | Improves space utilization effectiveness by 25%. |

| Low Maintenance | Requires less maintenance than other material handling systems. | Maintenance costs reduced by 50% over traditional systems. |

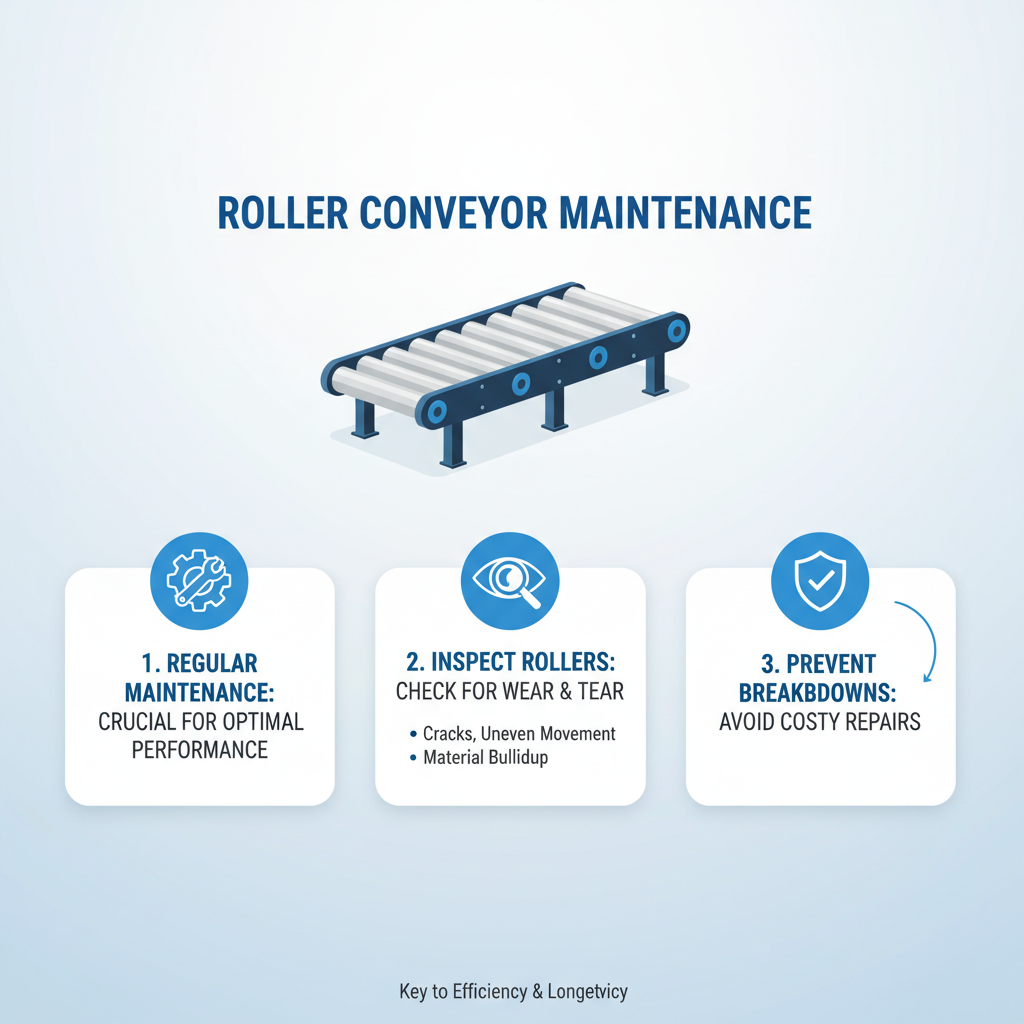

To ensure optimal performance of roller conveyor systems,

regular maintenance is crucial. One key aspect of maintenance is the inspection of rollers

for wear and tear. Over time, materials can cause friction and degradation, leading to reduced

efficiency and potential breakdowns. Regularly checking for signs of damage, such as cracks or

uneven movement, can prevent minor issues from escalating into costly repairs.

Another vital consideration is the lubrication of moving parts.

Proper lubrication reduces friction between components, enhancing the smooth operation of the conveyor.

It's essential to follow the manufacturer's guidelines on lubrication intervals and the types of oil

or grease to use, as improper lubrication can lead to increased wear and energy consumption.

Additionally, cleaning the conveyor to remove dust, debris, and other contaminants helps maintain

optimal performance and extends the lifespan of the

conveyor system. Implementing a scheduled maintenance program that addresses these aspects will

ensure that roller conveyor systems operate efficiently and reliably, significantly benefiting

material handling processes.