As the manufacturing landscape continues to evolve, automation conveyor systems have become a pivotal component in enhancing operational efficiency and productivity. Industry expert Dr. Lucy Harrington, a leading researcher at the Institute of Manufacturing Automation, emphasizes the transformative power of these systems, stating, "Automation conveyor systems are not just a technological advancement; they represent a fundamental shift in how manufacturing can optimize workflows and reduce costs."

The integration of automation conveyor systems streamlines processes, minimizes human error, and accelerates production rates, making them an essential asset for modern manufacturing environments. By facilitating smooth material handling and logistics management, these systems enable manufacturers to respond swiftly to market demands and adapt to changes in production schedules. As we delve into the top ten benefits of automation conveyor systems, it becomes clear that their role extends beyond mere mechanization; they embody the future of efficient and sustainable manufacturing practices.

In an era where efficiency is paramount, organizations that leverage automation conveyor systems are poised to gain a competitive advantage, ultimately reshaping the way goods are produced and delivered. The benefits are numerous and varied, promising to elevate not just productivity but also employee safety and operational versatility in an increasingly complex manufacturing world.

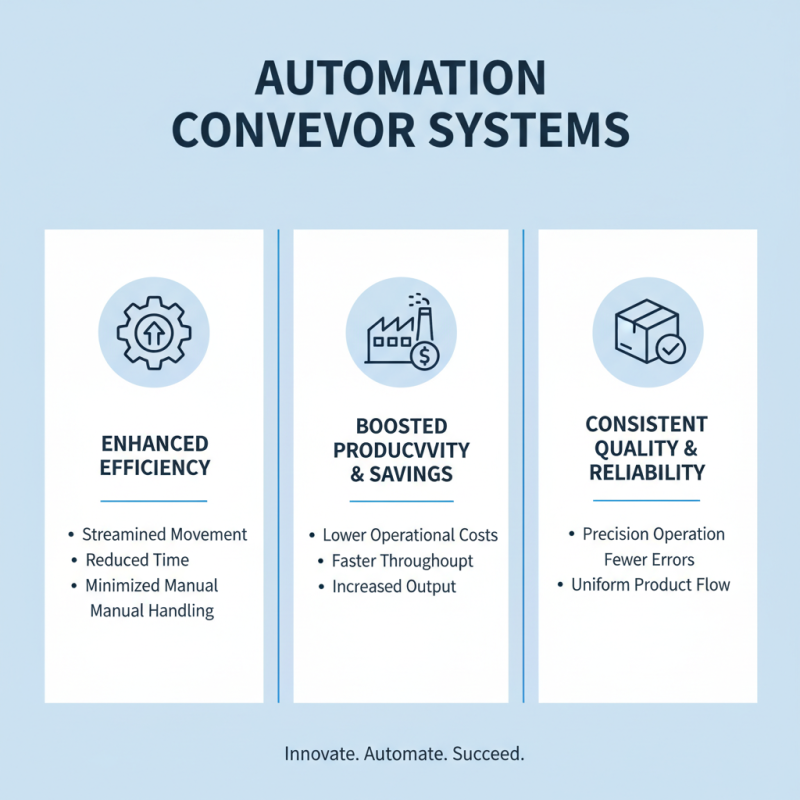

In today's fast-paced manufacturing environment, automation conveyor systems play a vital role in enhancing efficiency. These systems streamline the movement of goods and materials through production processes, significantly reducing the time required for tasks that would otherwise be labor-intensive. By minimizing manual handling and ensuring that products are transported smoothly, companies can boost productivity while lowering operational costs. Furthermore, automated conveyor systems help in maintaining consistent output quality, as they are designed to operate with precision and reliability.

Tips for maximizing the benefits of automation conveyor systems include regularly maintaining the equipment to prevent any disruptions and ensuring staff are adequately trained to operate the systems efficiently. Implementing data analytics can also provide insights into performance, allowing for optimization of workflows. Additionally, integrating these systems with other automation technologies can create a more seamless manufacturing environment, driving even greater efficiency and faster turnaround times.

Overall, the integration of automation conveyor systems leads to a significant enhancement in operational efficiency. By reducing delays and improving the workflow, manufacturers can respond more swiftly to market demands, ultimately achieving a competitive edge in the industry. Embracing these technologies not only streamlines operations but also sets the foundation for future advancements in manufacturing processes.

Automated conveyor systems are revolutionizing the landscape of modern manufacturing by significantly reducing labor costs, which is a vital advantage for companies aiming to increase profitability. By integrating automated conveyor solutions, manufacturers can streamline their operations, minimizing the need for manual handling. This not only cuts down on wages but also reduces the expenses associated with hiring, training, and maintaining a workforce. Through improved efficiency, these systems allow for better allocation of human resources to more strategic tasks, further enhancing productivity.

Moreover, automated conveyor systems improve consistency and accuracy in material handling, which leads to fewer errors and reworks. This reduction in production discrepancies not only saves time but also decreases the overall cost associated with quality assurance and management. By leveraging technology, businesses can maintain higher levels of output without the proportional increase in labor costs, ultimately driving down the total cost of production while boosting the bottom line. Implementing these automated solutions positions manufacturers competitively in the market, as they can respond swiftly to demand changes while managing expenses effectively.

In today's fast-paced manufacturing environment, the implementation of automation conveyor systems has become crucial for enhancing workplace safety. One of the primary benefits of these systems is their ability to significantly minimize human error, which is a leading cause of accidents on the factory floor. According to a report by the National Safety Council, nearly 90% of workplace injuries are attributable to human mistakes. By integrating automation, companies can reduce the reliance on manual labor for repetitive and hazardous tasks, thereby decreasing the likelihood of injuries and enhancing overall operational safety.

Automated conveyor systems streamline the movement of materials and products, reducing the need for employees to traverse potentially dangerous areas. This not only minimizes the risk of slips, trips, and falls—responsible for about 27% of non-fatal workplace injuries—but also enables workers to devote their efforts to more skilled and less risky tasks. A study by the Manufacturing Institute noted that organizations implementing advanced automation technologies have seen a 60% reduction in workplace accidents, highlighting the effectiveness of such systems in providing a safer work environment. With automation, manufacturers can cultivate a culture of safety that prioritizes employee well-being while optimizing productivity and efficiency.

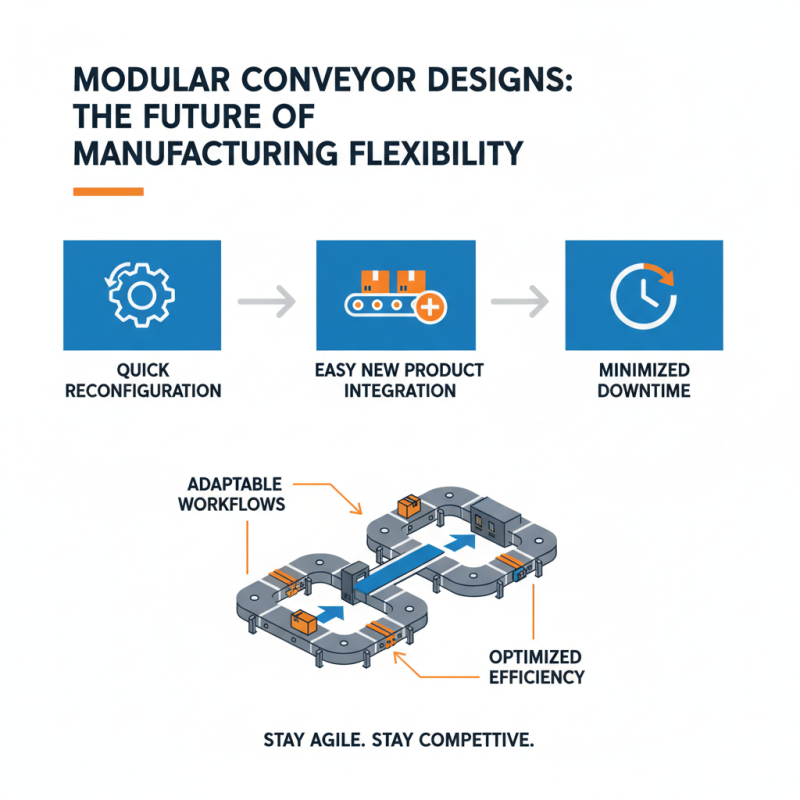

In modern manufacturing, flexibility is key to staying competitive, and modular conveyor designs are revolutionizing the way production lines operate. These systems allow manufacturers to easily reconfigure their workflows to accommodate varying production demands, all while optimizing efficiency. Modular conveyor designs facilitate quick changes to line layout, making it easier to introduce new products or adjust existing ones without the need for extensive downtime. This adaptability is particularly valuable in industries where demand can fluctuate rapidly, ensuring that businesses remain agile and responsive.

Tips for leveraging modular conveyor systems effectively include assessing current workflows to identify bottlenecks that can be alleviated with better layouts. Additionally, consider using conveyor segments that can be easily added or removed, as this will enhance the ability to pivot toward new projects with minimal disruption. Regular training sessions for staff on how to utilize these systems can also yield substantial productivity gains, making the most of the enhanced flexibility that modular designs provide. By focusing on these key areas, manufacturers can harness the true potential of automation and stay ahead in a continually evolving market.

Real-time data monitoring and analysis in automated conveyor systems revolutionizes manufacturing by enhancing operational efficiency and decision-making processes. These systems are equipped with advanced sensors that continuously track the movement of materials along the conveyor, generating valuable data about workflow patterns, throughput rates, and equipment status. By collecting this information in real-time, manufacturers can identify bottlenecks, optimize resource allocation, and reduce downtime, leading to a more streamlined production line.

Moreover, the ability to analyze this data allows manufacturers to implement predictive maintenance strategies. By monitoring machine performance trends, operators can foresee potential failures before they occur, ensuring that machinery is serviced at the right time. This proactive approach minimizes disruptions in production and maximizes the lifespan of equipment. Additionally, real-time insights empower managers to make informed decisions quickly, adapt to changing production demands, and enhance overall productivity, positioning their operations for success in a competitive market.

| Benefit | Description | Impact on Manufacturing | Real-Time Data Monitoring |

|---|---|---|---|

| Increased Efficiency | Automation reduces manual labor, speeding up production processes. | Higher output with lower operational costs. | Monitor throughput and bottlenecks continuously. |

| Enhanced Accuracy | Minimizes human error in handling materials. | Improved product quality and reliability. | Track precision of operations in real-time. |

| Cost Savings | Reduction in labor costs and operational expenses. | More budget for innovation and growth. | Analyze cost trends through data insights. |

| Flexibility | Easily adjustable to different products or production lines. | Scalable operations to meet demand fluctuations. | Collect data on production shifts rapidly. |

| Increased Safety | Reduces the need for manual handling of heavy materials. | Lower accident rates in the workplace. | Track safety metrics using real-time data. |

| Improved Workflow | Streamlined processes reduce delays and interruptions. | More organized production schedules. | Identify process inefficiencies through data analytics. |

| Better Inventory Management | Automated systems help track materials in real-time. | Reduced stock shortages or overages. | Real-time updates on inventory levels. |

| Consistency | Uniform processing times and outputs. | Enhances brand reputation for reliability. | Monitor consistency metrics effectively. |

| Data-Driven Decisions | Access to real-time data improves decision-making. | Enhanced strategic planning capabilities. | Utilize analytics for continuous improvement. |