Automation technology is revolutionizing industries globally. According to a recent McKinsey report, automation could raise productivity by 0.8 to 1.4 percent annually. This shift is not merely about efficiency; it signifies a fundamental change in how businesses operate. The integration of robotics and AI is enhancing capabilities in manufacturing, healthcare, and logistics.

However, the transition is not without challenges. Many workers face job displacement due to automation. A World Economic Forum study indicates that automation may replace 85 million jobs by 2025. Companies must navigate this complex landscape, balancing innovation with social responsibility. The potential economic benefits are immense, but the societal impact raises critical questions.

In the broader scope, automation technology facilitates real-time data analysis and enhances decision-making processes. For instance, in manufacturing, automation leads to reduced costs and improved quality control. Yet, this does not guarantee success for all. Companies must adapt strategically to leverage automation’s advantages without compromising their workforce.

Automation technology refers to the use of control systems for operating equipment. This includes machinery, processes in factories, boilers, and heat treating ovens. Key components involve sensors, actuators, and software. Together, they work seamlessly to automate tasks.

Sensors are crucial. They gather data about the environment. This data helps machines make decisions. Actuators follow, converting this data into physical action. They perform tasks like moving an assembly line. Software ties everything together, interpreting sensor data and directing actuators effectively.

**Tip:** When implementing automation, consider starting small. Test with a single process before expanding. This allows for adjustments without overextending resources. Automation can fail if the initial setup isn't well thought out.

Another important aspect is regular maintenance. Systems may require updates or repairs. Neglecting this can lead to significant downtime. High costs may follow unexpected failures. **Tip:** Schedule routine check-ups for your automated systems to ensure smooth operation and longevity. Remember, even the best technology needs care.

| Key Components | Description | Industry Impact | Examples of Use |

|---|---|---|---|

| Robotics | Machines designed to perform tasks autonomously or semi-autonomously. | Increases efficiency and safety in manufacturing. | Assembly lines, packaging, material handling. |

| Artificial Intelligence | Technology that enables machines to learn and make decisions. | Enhances decision-making processes and personalizes customer experiences. | Customer service chatbots, predictive analytics. |

| IoT (Internet of Things) | Network of devices that communicate and exchange data. | Improves monitoring and management of resources. | Smart factories, connected vehicles, energy management systems. |

| Process Automation Software | Software designed to automate repetitive tasks. | Reduces human error and frees up employee time. | Data entry automation, workflow management. |

| Machine Learning | A subset of AI that enables systems to learn from data. | Optimizes performance and adapts to new data trends. | Fraud detection, customer segmentation, supply chain optimization. |

The historical development of automation technology has been profound across various industries. Early automation began in the manufacturing sector. The advent of the assembly line, for instance, revolutionized how products were made. Reports indicate that production efficiency increased by 50% during this shift.

In agriculture, advancements like automated irrigation and precision farming have transformed crop yields. Studies show that productivity in smart farming can rise by 20-30%. Unexpectedly, though, the transition brought challenges. Workers had to adapt to new techniques quickly, and not all were able to keep up.

**Tips:** Embrace continued education in technology. Workers need to maintain flexibility in job roles as automation progresses.

In logistics, automation plays a critical role. Automated warehouses and delivery systems can process orders with precision. However, with this efficiency, the need for skilled workers to manage these systems increases. A study by the International Federation of Robotics highlights that skilled labor is still needed despite automation.

**Tips:** Analyze community resources that offer training programs. Local initiatives can help bridge the skills gap.

Reflecting on these developments, it is clear that automation reshapes industries. Yet, there remains a pressing need to consider the human element in this evolving landscape.

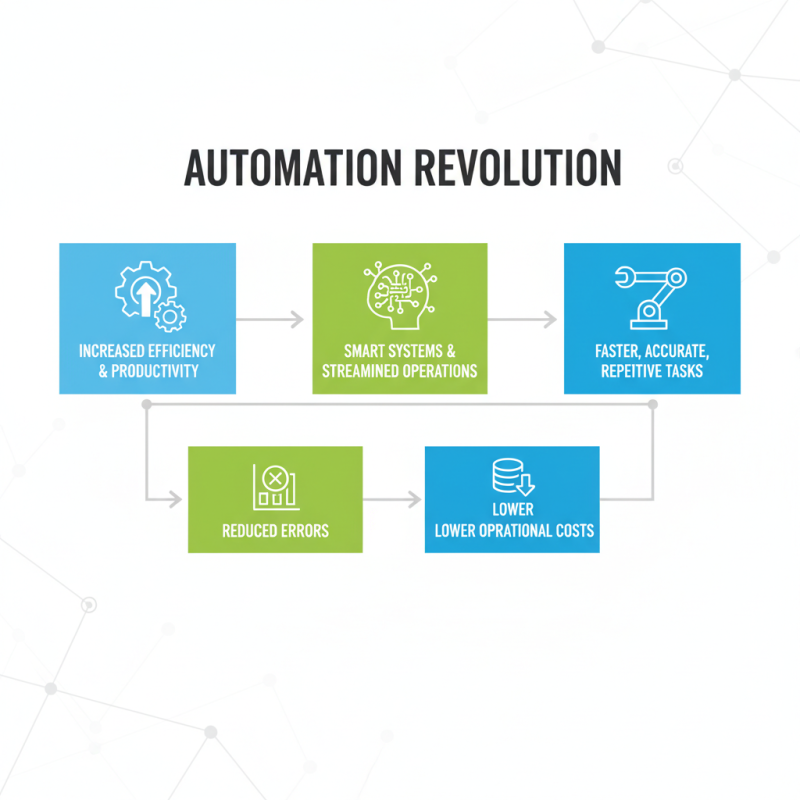

Automation technology is revolutionizing industries by enhancing efficiency and productivity. By incorporating smart systems, businesses streamline their operations. Machines can perform repetitive tasks faster and more accurately than humans. This results in reduced errors and lower operational costs.

In factories, for instance, robots assemble products at a rapid pace. Workers can then focus on more complex tasks, which require critical thinking. However, this shift comes with challenges. Not all workers are prepared for this transition. Skill gaps emerge as some roles become obsolete.

Moreover, automation can lead to over-reliance on technology. If systems fail, production can halt entirely. Companies must strike a balance between automation and human oversight. While technology boosts productivity, it's crucial to maintain a human touch in processes. Adapting to this new landscape requires ongoing training and reassessment.

Automation technology is revolutionizing industries, but it's not without challenges. One major risk is job displacement. As machines take over tasks, workers may find themselves obsolete. This shift can lead to economic instability for families. Companies must plan for retraining and upskilling employees to ease this transition.

Integration of automation systems can also be complex. Companies may underestimate the costs and time required for implementation. Technical issues often arise, slowing down processes. A poorly executed automation system can result in more problems than it solves. It's critical for organizations to conduct thorough assessments. They need to understand their needs and the technology’s limitations.

Security is another concern. Automated processes can be vulnerable to cyber threats. A breach could compromise sensitive data and disrupt operations. Therefore, investing in robust cybersecurity measures is essential. Organizations must continuously evaluate risks. They should stay updated on the latest security practices. By doing so, they can protect their assets while embracing automation.

Automation technology is rapidly evolving and shaping the future of various industries. Reports forecast that the global market for automation will reach over $300 billion by 2026, growing at a CAGR of 9% from 2021 to 2026. This growth is driven by significant advancements in artificial intelligence, robotics, and machine learning. These technologies enable more efficient processes and reduce human error, reshaping how businesses operate in manufacturing, logistics, and even healthcare.

Future trends suggest that automation will lead to greater job displacement but also the creation of new roles. It’s estimated that by 2030, 80 million jobs could be lost to automation, yet 97 million new jobs may emerge. Organizations should be mindful of this double-edged sword. There’s a strong need for reskilling initiatives to prepare the workforce for the changes ahead. While automation promises efficiency, it raises questions about equity and accessibility for workers. Moreover, industries should not overlook the importance of ethical considerations in deploying these technologies. The challenge lies in balancing innovation with responsible usage.