In today's fast-paced business environment, efficiency and productivity are more crucial than ever. As companies strive to streamline their operations, automated packaging solutions have emerged as a game-changing innovation. By integrating automated packaging processes into business workflows, organizations can significantly reduce labor costs, minimize human error, and enhance overall operational efficiency. This transition not only helps businesses scale their operations but also ensures consistency in product presentation and improves customer satisfaction.

The implementation of automated packaging technology involves several strategic considerations, including assessing specific needs, selecting the right technology, and training staff to ensure smooth integration. Moreover, it is essential for businesses to analyze their current packaging processes to identify areas where automation can provide the most significant benefits. By focusing on these key aspects, companies can create a tailored approach that maximizes the advantages of automated packaging while meeting their unique operational demands. As the packaging landscape continues to evolve, embracing these solutions will be vital for businesses aiming to thrive in a competitive market.

Automated packaging solutions have emerged as a vital component in enhancing efficiency across various sectors. The growing demand for faster production cycles and higher quality outputs has led businesses to adopt innovative packaging technologies. These solutions encompass a range of automation systems that streamline the packaging process, from wrapping and sealing to labeling and sorting. By integrating automated systems, companies can significantly reduce labor costs and minimize human error, ensuring a consistent flow of products to market.

Moreover, the benefits of automated packaging extend beyond mere operational efficiency. The implementation of such solutions often results in improved sustainability practices, as many automated systems are designed to optimize material usage and reduce waste. Industry trends also indicate a shift towards smart packaging technologies, which leverage IoT and AI to enhance tracking and quality control. This convergence of technology not only elevates productivity but also fosters a more sustainable approach to packaging, aligning with the growing consumer preference for eco-friendly practices. As businesses continue to embrace automation, they position themselves to meet the evolving demands of the market while contributing to environmental stewardship.

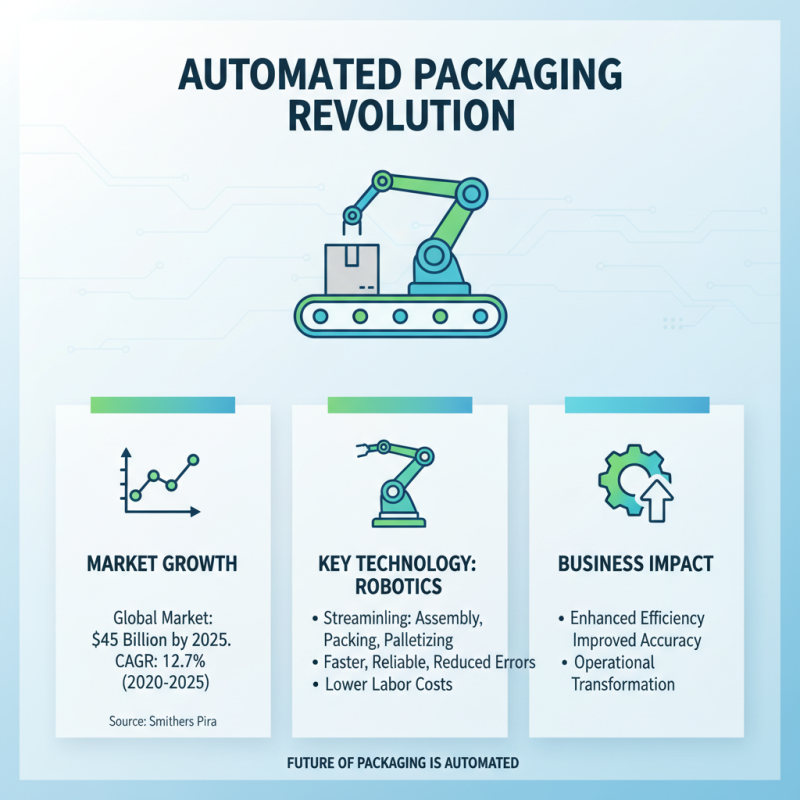

Automated packaging solutions are rapidly transforming the way businesses operate, driven by key technologies that enhance efficiency and accuracy. According to a report by Smithers Pira, the global market for automated packaging is projected to reach approximately $45 billion by 2025, reflecting a compound annual growth rate (CAGR) of 12.7%. Central to this growth is robotics, which is streamlining processes such as assembling, packing, and palletizing. Robotic arms can perform repetitive tasks reliably and at greater speeds than human labor, resulting in reduced labor costs and minimized human error.

Another significant technology shaping automated packaging is artificial intelligence (AI). AI-driven systems can analyze vast amounts of data from various processes, enabling predictive maintenance and optimizing workflow. According to a study by the Packaging Automation Alliance, implementing AI can enhance packing speed by up to 30%, which significantly contributes to overall productivity. Additionally, IoT (Internet of Things) technologies facilitate real-time monitoring of packaging equipment, allowing for immediate troubleshooting and maintenance.

**Tips:**

1. Evaluate your current packaging processes to identify bottlenecks that can be improved with automation.

2. Invest in scalable technology solutions that can grow with your business needs, ensuring long-term efficiency.

3. Provide training for your staff on the new technologies to maximize their effective use and integration into existing workflows.

When considering the implementation of automated packaging solutions, conducting a detailed cost-benefit analysis is crucial for understanding the return on investment (ROI). The initial investment in automation technology may seem daunting, but businesses should weigh it against potential long-term savings and efficiency improvements. Key factors to consider include labor costs, packaging materials, and the speed of production. By reducing manual labor and minimizing material waste, companies can enhance their overall productivity while maintaining the quality of their packaging.

Tips for evaluating ROI: Compare current operational costs and projected savings with automation. Utilize detailed metrics such as labor hours saved, reduction in product damage during handling, and improved shipping accuracy. Engage with finance teams to model different scenarios, from optimistic to conservative forecasts, to get a clearer picture of potential gains.

Additionally, analyzing customer satisfaction can provide qualitative measurements of success. Automated packaging can lead to faster turnaround times and consistent quality, which can positively impact customer retention and loyalty. When assessing the overall results, consider both quantitative data and qualitative feedback to get a comprehensive understanding of the automated system's effectiveness in your business context.

Integrating automation into existing packaging lines can significantly enhance operational efficiency and product consistency. One of the best practices is to conduct a comprehensive audit of the current packaging processes. This allows businesses to identify bottlenecks and areas where automation can be most beneficial. Collaborating with employees who operate the packaging lines will provide valuable insights into daily challenges and workflow inefficiencies that automation can resolve. By gathering this information, companies can tailor their automation solutions to address specific needs, ultimately leading to a smoother transition.

Another critical practice is to invest in modular and scalable automation technologies. These solutions can be gradually integrated into existing systems, minimizing disruption while maintaining production output. Training staff on new technologies is equally important, as it helps to alleviate fears about change and fosters a culture of innovation. Continuous monitoring and feedback loops should be established once automation is implemented, allowing for ongoing assessments and adjustments. This iterative approach ensures that the automated systems evolve alongside the business needs, driving sustained improvements in packaging efficiency.

| Packaging Process | Automation Level | Efficiency Gain (%) | Cost Reduction (%) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Carton Filling | 80% | 20% | 15% | 6 |

| Labeling | 75% | 25% | 10% | 4 |

| Sealing | 90% | 30% | 20% | 5 |

| Palletizing | 85% | 22% | 18% | 7 |

| Inspection | 70% | 10% | 12% | 3 |

Automated packaging solutions have proven to be transformative for businesses across various industries, enhancing efficiency and reducing operational costs. One standout case is a mid-sized e-commerce company that faced challenges with increasing demand and labor shortages during peak seasons. By implementing an automated packing system, they managed to streamline their order fulfillment process. The technology not only accelerated packaging times but also improved accuracy, resulting in fewer returns due to packing errors. This shift led to a significant increase in customer satisfaction and retention, while also freeing up employees to focus on higher-value tasks within the business.

Another compelling example can be found in the food and beverage sector, where a manufacturer sought to modernize its aging packaging line. The integration of automated machinery allowed them to handle a wider variety of product types with greater speed and efficiency. Ultimately, this implementation resulted in a 30% reduction in labor costs and a remarkable decrease in product waste. Additionally, the real-time data provided by advanced packaging solutions enabled the company to identify bottlenecks quickly and adjust processes accordingly. These successful implementations highlight how automated packaging not only enhances operational efficiency but also positions businesses to respond dynamically to market demands.