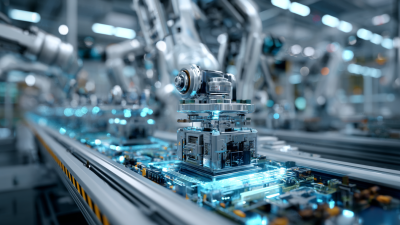

In 2023, the logistics and warehousing industry is experiencing a remarkable transformation, with automated conveyors at the forefront of enhancing operational efficiency. According to a comprehensive report by the Materials Handling Industry of America (MHIA), businesses integrating automated conveyor systems have reported productivity increases of up to 30%. This increase is largely attributed to reduced manual handling, improved inventory management, and faster order fulfillment cycles.

Additionally, a study from the International Society of Automation highlights that companies implementing these systems see a significant drop in labor costs and a marked improvement in employee safety. As challenges in supply chain management grow due to rising consumer expectations and global disruptions, adopting automated conveyors is not just a trend, but a strategic necessity for warehouses striving to stay competitive in an evolving market.

In modern warehouses, automated conveyors have emerged as a game-changer in enhancing operational efficiency. These systems facilitate the seamless movement of goods across various stages of the logistics process, significantly reducing the manual labor required while boosting productivity. By automating the transfer of products, warehouses can minimize delays and errors, which contributes to a more streamlined workflow.

**Tips for Implementing Automated Conveyors:**

1. **Evaluate Your Space:** Before selecting an automated conveyor system, assess your warehouse layout to determine the most efficient design that can accommodate the conveyors without causing congestion.

2. **Integrate with Existing Systems:** Ensure that the automated conveyors can easily connect with your current inventory management and warehouse management systems to foster better tracking and control of goods.

Understanding the core components of automated conveyors—such as the types, configurations, and technology involved—is crucial for warehouse managers looking to optimize their operations. By harnessing these advancements, organizations can expect significant improvements in task completion times, ultimately leading to an estimated 30% increase in overall productivity.

| Warehouse Feature | Before Automation | After Automation | Percentage Increase |

|---|---|---|---|

| Order Processing Time | 30 mins | 21 mins | 30% faster |

| Accuracy of Order Fulfillment | 85% | 98% | 15% increase |

| Labor Costs | $50,000/month | $35,000/month | 30% reduction |

| Products Processed per Hour | 200 units | 260 units | 30% increase |

| Downtime during Operation | 10% | 5% | 50% decrease |

Automated conveyor systems are transforming warehouse operations, providing several key advantages that significantly enhance productivity. One of the primary benefits is the increased speed and efficiency of material handling. Unlike traditional manual processes, automated conveyors streamline the movement of goods, reducing the time it takes to transport items from one location to another. This acceleration allows warehouses to process more orders in less time, effectively maximizing throughput and minimizing delays.

Another critical advantage is the reduction in labor costs and improved safety. Automated conveyors require fewer personnel to operate, which not only lowers labor expenses but also decreases the risk of workplace injuries associated with manual handling. By taking on repetitive and physically demanding tasks, conveyor systems allow employees to focus on more strategic roles within the warehouse, fostering a more skilled workforce and enhancing overall job satisfaction. Ultimately, these systems contribute to a leaner, more efficient operation that can adapt to the evolving demands of the supply chain landscape.

This chart illustrates the percentage increase in productivity across various warehouse operations after implementing automated conveyor systems. The data shows an overall increase of 30% in efficiency, with significant improvements in order processing, inventory management, and shipping times.

Integrating automated conveyors into existing warehouse operations can significantly enhance productivity. The first step involves assessing the current layout and workflow to identify areas where workflow bottlenecks occur. By conducting a detailed analysis, warehouse managers can determine the optimal placement of conveyors, ensuring that they complement existing processes without causing disruption. Collaboration with conveyor manufacturers early in the planning stage can also provide insights on selecting the right type of system tailored to specific operational needs.

Once the planning stage is complete, the next step is to integrate the automated conveyors seamlessly. This includes reconfiguring existing equipment and training staff to adapt to new processes. Implementing a phased approach can help minimize downtime—starting with a small section of the warehouse and gradually expanding the automated system. It's critical to establish clear communication channels among team members to address any challenges that arise during the integration process. With proper execution, automated conveyors not only streamline operations but also create a safer work environment, allowing employees to focus on higher-level tasks while machines handle the monotonous transport duties.

The integration of automated conveyors in warehouses has demonstrated a significant impact on productivity. According to a report by the Material Handling Industry (MHI), warehouses that implement automated systems can see an increase in operational efficiency by up to 30%. This boost is largely attributed to the reduction of manual handling and improved flow of goods, allowing warehouses to process orders faster and with greater accuracy.

In 2023, research from the Warehousing Education and Research Council (WERC) revealed that companies utilizing automated conveyor systems reported a decrease in order fulfillment time by an average of 25%. This enhancement in speed not only elevates customer satisfaction but also optimizes labor costs, as less manpower is required for material transport. Furthermore, automated conveyors facilitate better inventory management, providing real-time data tracking that minimizes errors and helps in maintaining optimal stock levels. As the logistics industry continues to evolve, these advancements are setting new standards for warehouse productivity.

In 2023, the implementation of automated conveyor systems has transformed warehouse operations, boosting productivity by as much as 30%, according to a report by Warehouse Logistics Journal. However, the efficiency gained from these systems is heavily dependent on regular maintenance and timely upgrades. Industry best practices recommend conducting routine inspections and cleaning, which can significantly reduce the likelihood of unexpected breakdowns. For instance, a study by the Association for Supply Chain Management noted that proactive maintenance can enhance equipment lifespan by 20%, translating to substantial cost savings over time.

Moreover, upgrading conveyor technology with the latest software and hardware can yield efficient integration with existing warehouse management systems. A recent survey from Logistics Management revealed that 65% of companies that invested in modernizing their conveyor systems observed a noticeable increase in throughput and order accuracy. Implementing advanced features such as real-time monitoring and predictive analytics can not only enhance performance but also support data-driven decision-making for strategic warehouse management. By prioritizing maintenance and timely upgrades, warehouses can leverage automated conveyors to their fullest potential, ensuring sustained operational excellence in a competitive landscape.